What is Aluminum Sand Casting

Aluminum sand casting is the process of forming aluminum into a mold pattern formed in sand. Almost 60 percent of all metals are produced using the sand casting process. Most aluminum castings are usually made in sand molds.

Why Choose Us

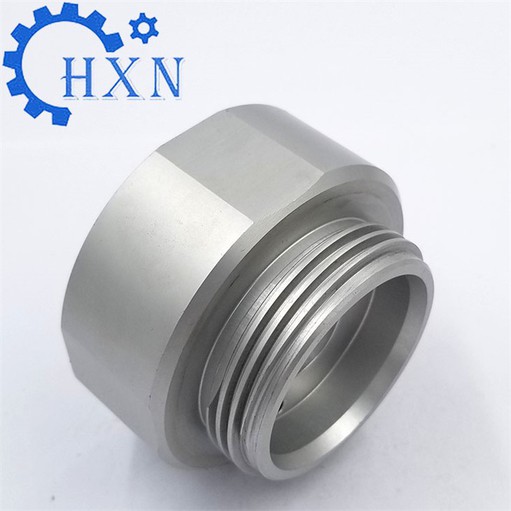

Our Equipment

HXN has precision casting production line and more than 60 kinds of machining equipments. Such as CNC lathes, Swiss CNC Lathe machine, 4 Axis machining centers, 5 Axis machining centers, wire cutting machines, milling machines, drilling machines and other equipments at state-of-the-art.

Our Product

We specialize in manufacturing non-standard customized parts, the main processes are precision casting and CNC machining. Our product includes all materials, carbon steel, alloy steel, stainless steel, brass, and aluminum.

Our Certificate

We always feel that all success of our company is directly related to the quality of the products we offer. They meet the highest quality requirements as stipulated in ISO9001, ISO14000:14001 SGS guidelines, and our stringent quality control system.

Production Market

We have customers from both the domestic market and the oversea market. Sales managers can speak fluent English for good communication. The total value of output is up to 5 million USD, exported to more than 20 countries. HXN products are widely used in the flow control industry and various kinds of equipment.

Advantages of Aluminum Sand Casting

Cost-Effectiveness: Sand casting is relatively cost-effective compared to some other casting methods. The raw materials, namely sand and aluminum, are readily available and affordable, making it an attractive option for both small-scale and large-scale production.

Versatility: Sand casting is incredibly versatile, allowing for the creation of complex shapes and intricate details. It can be used to produce a wide range of aluminum components, from engine blocks to ornamental pieces.

Mold Reusability: Sand molds are reusable, leading to significant cost savings over time. This is especially advantageous in scenarios where multiple identical parts need to be cast.

Low Tooling Costs: Unlike high-pressure casting, which often requires expensive dies and molds, sand casting relies on relatively low-cost tooling. This makes it an accessible option for smaller businesses and startups.

Which Industries Are Served by Aluminum Sand Casting?

CONSUMER GOODS: From appliance parts to aluminum cookware to lawn care equipment, sand casting capabilities are a perfect fit for the consumer home goods industry. Leading manufacturers of merchandise found in marine engines, motorcycles, snow mobile, and grill bodies turn for aluminum casting services.

AGRICULTURE: Agriculture applications for our casting capabilities include measuring and control devices, valves, and field equipment parts. Our high pressure sand casting services are up to the challenge of manufacturing agricultural parts. Whether it is pickers and spreaders, ag waste removal equipment, tractor parts, or other farm equipment, we have you covered.

MILITARY/DEFENSE APPLICATIONS: We are proud to serve customers in the defense industry. From helicopter parts to flight control equipment, from missile launch technology to Special Ops field equipment, the military applications of our casting capabilities are wide-ranging.

Applications of Aluminum Sand Casting

Automotive Industry

The lightweight properties of aluminum sand casting make vehicles more energy-efficient and environmentally friendly, while providing good strength and rigidity. Aluminum alloys are used in engine parts, chassis components, suspension systems, exhaust systems, aluminum wheels, and other parts.

Aerospace Industry

The high strength and lightweight characteristics of aluminum alloys make them suitable for structural components and engine assemblies, such as aircraft flaps, propellers, and fuselage components.

Electronics

Good thermal conductivity and corrosion resistance allow for effective heat management and external protection. Aluminum sand casting are primarily used in components such as casings, enclosures, and heat sinks.

Industrial Equipment

Pumps, valves, compressors, and mechanical components benefit from the high strength and excellent corrosion resistance of aluminum alloys, enabling them to meet the requirements of various industrial environments.

Sporting Equipment

The lightweight and excellent strength of aluminum alloys make them suitable for applications in bicycles, golf clubs, boats, and camping equipment, providing durability and strength.

Construction Industry

The excellent ductility and machinability of aluminum sand casting allow for various complex architectural grid designs. The lightweight and high strength characteristics provide structural stability and support, while the good corrosion resistance ensures long-term appearance and performance in outdoor conditions.

Process and Production of Aluminium Sand Casting

Aluminium sand casting is most commonly used to make metal castings. The technology uses one-shot sand molds to cast complex parts of nearly any metal alloy, including cast aluminum alloys. Sand castings are generally less productive because the sand must be broken to remove the finished casting.

Aluminium sand casting process

Aluminium sand casting techniques include the use of: melting (holding) furnaces, foundry molds and sand molds. Cast aluminum alloys are first melted in an oven and then poured through a ladle, usually by hand, into the cavity of a sand mold. This cavity in the mold is formed using a mold casting model (usually wood). After the metal is fully solidified, the sand mold is separated along the parting plane and the solidified casting is taken out.

Sand casting is used to produce various metal parts with complex geometries. These high pressure castings vary widely in size and weight, ranging from hundreds of grams to tons. Aluminium sand casting produces many automotive aluminium castings and components: cylinder blocks and cylinder heads, transmissions, housing unit chassis and many more.

The production of aluminium sand casting

The first step in the aluminum sand casting process is to create a mold for casting. Sand molds are disposable, so each casting has to be remade. Sand molds are formed by compacting sand in each of the two mold halves. Sand stuffing around the model is an imprint of the casting shape. When the model is withdrawn, it is in the form of a cavity that will form the casting. To generate any internal cavity of the casting, the model cannot be generated, using the form of a single component, the so-called rod. These rods are also made of sand before forming the mold.

The sand casting mold making process includes: installing the model; compacting the sand; removing the model. The duration of making the sand mold depends on: the size of the casting; the number of rods; the sand mold. If the type of sand mold requires heating or baking, the duration of its production is greatly increased. Also, the mold surfaces are often lubricated to make removal of the finished casting easier. The application of lubrication also promotes the flow of metal and improves the quality of the casting surface. Lubricants are selected based on the type of sand used and the melt temperature.

Once the aluminum sand casting has been molded, it is ready to pour molten metal. The surface of the mold is first smeared to ensure the free removal of the casting. The core is then set, the upper die is mounted on the lower die and they are firmly connected. It is very important to keep the two halves of the mold firmly closed to prevent any metal flow.

The process works this way:

We create a pattern in the shape of the OEM made part. The patterns can be made from a variety of materials and can be very intricate in design.

The sand is poured, packed and bonded around the pattern to form a cavity (in two halves). We then combine the halves to form the mold. We also form one or more "runners" in the mold. These are the openings through which the metal will enter the mold.

We pour molten metal material into the mold through one or more runners.

The metal cools and solidifies.

We break the sand mold away and remove the finished part.

Aluminum casting processes can be broken down into different types as listed below:

Die Casting:

Die casting uses a hardened steel, two-part cavity tool, in which molten aluminum is poured or forced. These tools generally have 100,000 to 150,000 cycles of shot life and produce high-accuracy and high-quality parts. Die casting ranges from using simple tools with hand-poured fill-up to completely automated systems for very high volumes.

Investment Casting:

This process uses a sacrificial positive model of the required part. Before molten aluminum is poured into the plaster form, the wax is vaporized or driven out by baking the plaster tool. The cavity retains its shape and is then filled with molten metal that cools quickly.

In a more up-to-date approach, the positive model used to cast the cavity can be cut from expanded polystyrene, or 3D printed in wax and potentially polymers such as PET and PLA. In the case of plastic "positives", they must also be burned out of the cavity to leave no residues. This process tends to be reserved for high-value and intricate parts. The tool is destroyed to extract the finished part.

Sand Casting:

Sand casting uses a stronger pattern part, generally from wood, and then packs this into two box halves, using sand with a binding agent, and talc as a release and separating agent. Cavities are usually filled by hand pouring, though automation is possible. This is usually referred to as sand casting and is widely employed in the manufacture of lower-volume and/or larger shot-weight castings. While good precision is possible, the destruction of the cavity tool makes this a one-shot process.

Permanent Mold Casting:

This process is analogous to die casting in that two permanent (often cast steel) mold halves are clamped together and the cavity filled, generally by hand pouring.

Lost Foam Casting:

Lost foam casting is identical to investment casting. The pattern, however, is made from low-density foamed polymer rather than wax.

Shell Mold Casting:

A refinement of basic sand casting uses resin-bonded sand cast around the pattern to form a strong shell. Two shells are fixed together to form a sacrificial (single-use) cavity that is filled with molten aluminum. This process makes casting cavities faster and at a lower cost than ordinary sand casting and is used for medium to large casts needing higher precision.

Vacuum Die Casting:

Vacuum die casting differs from pressure or gravity die casting in that it uses a reservoir below the casting tool and pulls the molten material up by a vacuum applied to the tool. This results in lower porosity and higher-quality parts and is slowly displacing older die-casting methods.

Ceramic Mold Casting:

This process casts a silicate slurry around a pattern and then either burns the volatiles from the slurry (Osborn-Shaw process) or bakes them off (Unicast process), leaving a ceramic cavity into which molten metal can be poured. In many regards, this process is analogous to shell mold casting.

Factors to Consider When Selecting Aluminum Sand Casting

When selecting aluminum sand casting as a manufacturing process, several key factors should be considered to ensure the best outcome for your project. Here are some of the critical factors to keep in mind:

Design Complexity:Aluminum sand casting is well-suited for producing complex shapes and designs that might be challenging or costly to manufacture using other methods.

Consider the intricacies of your design and whether sand casting can achieve the desired geometry and tolerances.

Material Properties:Aluminum alloys offer a range of mechanical and physical properties, including strength, ductility, corrosion resistance, and thermal conductivity.

Choose an aluminum alloy that meets the specific requirements of your application, such as weight, durability, and operating environment.

Production Volume:Sand casting is often cost-effective for low-to-medium production volumes but may not be the most economical choice for high-volume production.

Consider the scale of your production needs and whether sand casting aligns with your desired production volume and cost targets.

Surface Finish and Appearance:Sand casting typically produces a rougher surface finish than other casting processes, such as die casting or investment casting.

If a smooth surface finish is critical for your application, additional finishing operations like machining or sanding may be required.

Tolerances and Precision:Sand casting may not offer the tightest tolerances compared to other manufacturing processes.

Determine the tolerance requirements of your components and ensure that sand casting can meet those specifications.

Environmental Impact:Aluminum is a highly recyclable material, making it an environmentally friendly choice.

Consider the sustainability aspects of your manufacturing process, including the use of recycled aluminum and the environmental impact of sand casting operations.

Cost:Evaluate the overall cost of aluminum sand casting, including material costs, tooling, labor, and any secondary operations required to achieve the desired final product.

Compare the cost-effectiveness of sand casting with other manufacturing processes to determine the most economical option for your project.

Lead Time:Consider the lead time required for aluminum sand casting, including pattern making, casting, cooling, cleaning, and any additional finishing operations.

Ensure that the lead time aligns with your project schedule and delivery requirements.

How to Maintain Aluminum Sand Casting

Mold Care and Storage:Ensure that molds are cleaned thoroughly after each use to remove residual sand, metal, and other contaminants.Store molds in a dry, controlled environment to prevent moisture absorption and mold damage.Regularly inspect molds for cracks, wear, and other defects that could affect casting quality.

Sand Management:Use high-quality sand that meets the specific requirements of your casting process.Maintain proper sand mixture consistency to ensure mold strength and dimensional stability.Regularly test the sand for its physical properties, such as permeability, compaction ability, and refractoriness.

Controlling Casting Conditions:Monitor and maintain consistent melting temperatures to ensure proper metal flow and solidification.Control the pouring rate to prevent turbulence and air entrapment in the mold cavity.Optimize cooling rates to minimize thermal stresses and prevent cracking.

Inspection and Quality Control:Implement a rigorous inspection process to identify and address casting defects early.Use non-destructive testing methods like X-ray or ultrasonic inspection to detect internal defects.Maintain traceability records for each batch of castings to facilitate quality control and troubleshooting.

Post-Casting Treatments:Heat treat aluminum castings as necessary to improve mechanical properties like hardness, ductility, and corrosion resistance.Apply protective coatings or platings to enhance the part's appearance or protect it from the environment.

Equipment Maintenance:Regularly service and maintain casting equipment, including furnaces, ladles, and mold-making machinery.Replace worn or damaged components promptly to avoid casting defects.Keep equipment clean and free of debris to ensure optimal performance.

Training and Safety:Provide regular training to operators on safe casting practices, equipment operation, and quality control procedures.Implement safety measures to protect workers from hazards like molten metal splashes, heat exposure, and dust inhalation.

Continuous Improvement:Collect and analyze data on casting defects, production rates, and material usage to identify areas for improvement.Implement process improvements based on this data to enhance casting quality, reduce scrap rates, and improve overall productivity.

Our factory

We have precision casting production line and more than 60 kinds of machining equipments. Such as CNC lathes, Swiss CNC Lathe machine, 4 Axis machining centers, 5 Axis machining centers, wire cutting machines, milling machines, drilling machines and other equipments at state-of-the-art.

FAQ

Enable GingerCannot connect to Ginger Check your internet connection

or reload the browserDisable in this text fieldRephraseRephrase current sentenceEdit in Ginger×

Hot Tags: aluminum sand casting, China aluminum sand casting manufacturers, suppliers, factory, investment precision casting, investment casting, precise cast prototypes, precision die casting inc, precision casting company, stainless dowel pins