Advantages of China Silica Sol Precision Casting Parts Supplier

Qingdao Hai Xin Nuo Machinery Co., Ltd. Founded in 2008, Qingdao HaiXinNuo Machinery is a professional machinery company in the coastal city of Qingdao. Our business is involved in the manufacturing of machinery parts, standard parts, customized parts, welding, fixture as well as the design and manufacturing of non-standard equipment parts.

Our best-selling products include: High Precision Stainless Steel Impellers, Silica Sol Casting Parts SS316 Stainless Steel, Silica Sol Precision Casting Parts, Stainless Steel Silica Sol Casting, 304 Stainless Steel Casting, ss 304 Investment Casting, Lost Wax Precision Casting, Steel Casting Valve, Lost Wax Investment Casting, Investment Cast 316 Stainless Steel, etc.

Advanced equipment: A machine, tool or instrument designed with advanced technology and functionality to perform highly specific tasks with greater precision, efficiency and reliability.

Rich experience: Dedicated to strict quality control and attentive customer service, our experienced staff is always available to discuss your requirements and ensure complete customer satisfaction.

Quality control: We have built a professional QC team to accurately inspect every raw material and every process of production.

Customized services: Our team of experts will work closely with you to understand your needs and will provide solutions that are tailored to meet your expectations. We have OEM service and can process according to the drawings provided by customers.

Professional team: Our professional team collaborate and communicate effectively with one another, and are committed to delivering high-quality results. They are capable of handling complex challenges and projects that require their specialized expertise and experience.

Long warranty: We are confident in the quality of our products and are willing to provide you with long-term technical service support.

Introduction to Silica Sol Precision Casting Parts

Silica sol precision casting part is a form of investment casting. It can be mixed into a very low viscosity slurry when making molds. The result is a casting method that provides dimensionally accurate castings with an excellent as-cast surface finish. Silica sol has a wide dehydration temperature range, which not only destroys its bonding strength but also makes its three-dimensional structure more stable, resulting in higher bonding strength. It is a good inorganic binder for precision casting.

Precision casting refers to the general term for the process of obtaining castings with precise dimensions. Investment casting is also called lost wax casting. Its products are sophisticated, close to the final shape of the part, and can be used directly without machining or with a small amount of machining. This is an advanced near-net shape process. The process includes: selecting a suitable investment material (such as paraffin) to make an investment pattern; repeating the steps of dipping refractory coating (the main component is silica sol) and spraying refractory sand on the investment pattern, hardening the shell and drying; melting the inner investment pattern, Obtain the mold cavity; bake the shell to obtain sufficient strength and burn off the residual investment material; pour the required metal material; solidify and cool, shell, and remove sand to obtain a high-precision finished product.

Silica sol is used in precision casting. Due to its good bonding ability and filling performance, the shell made of it has high strength, high gloss, and easy demoulding, so it is widely used in this field. According to the specific user requirements, it is divided into surface silica sol and back silica sol, which consumes a lot.

Silica Sol Precision Casting Parts

Production line

CMM Testing Equipment

Benefits of Silica Sol Precision Investment Casting Parts:

Will allow very intricate castings to be produced with thin walls.

Great versatility; suitable for casting most metals.

Allows un-machinable parts to be cast accurately instead.

Excellent dimensional accuracy

Smooth surface finishes are possible with no parting line so machining and finishing are reduced or eliminated.

Silica Sol Precision Casting Parts Factory Product Recommendations

High Precision Stainless Steel Impellers:

A high precision stainless steel impeller is a rotating disc made of stainless steel that increases the pressure and flow of a fluid. Impellers are used in centrifugal pumps to transfer energy from the pump's motor to the fluid being pumped. The impeller speeds up the fluid radially outward from the center of rotation.

High Precision Stainless Steel Impellers are widely used in a variety of environments, running efficiency is also very high. The use of stainless steel material help to ensure its serving life, but also put an end to the short time of damage.

Silica Sol Casting Parts SS316 Stainless Steel:

Silica Sol Casting Parts SS316 Stainless Steel is the casting process that uses silica sol silica solution as the binder material to build the casting mod. The metal castings produced by silica sol casting have fine surfaces and high accuracy and the general dimensional tolerance grades up to CT4 - CT6. This process is the main investment casting process of HXN for stainless steel castings and alloy steel castings.

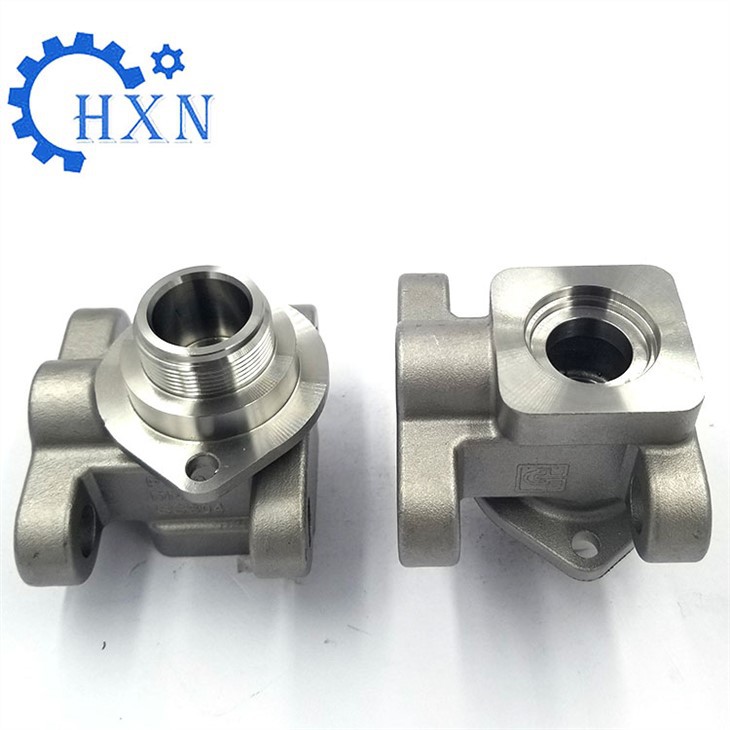

Silica Sol Precision Casting Parts:

Silica sol precision casting parts, also known as investment casting parts, are high-quality mechanical components that are made through a meticulous casting process. These parts are known for their superior quality and accuracy, making them ideal for use in a variety of industries.

Our silica sol precision casting parts are highly versatile and can be used in a wide range of applications. They are ideal for use in industries such as aerospace, automotive, electronics, and many more. Our parts are known for their ability to withstand extreme conditions and environments, making them highly durable and reliable.

Stainless Steel Silica Sol Casting:

Stainless steel silica sol casting is a type of investment casting that uses silica sol zircon sand as a molding material to produce stainless steel castings.

The silica sol casting process produces near-net-shape precision metal parts that often require little to no additional machining. The resulting finish is also much better than what is achievable through most other processes. And, the strength and durability of stainless steel silica sol casting parts make them ideal for high wear applications requiring millions of cycles.

304 stainless steel casting is a type of austenitic stainless steel that contains 18% chromium and 8% nickel. It's the most common grade of stainless steel casting and is known for its corrosion resistance and value. 304 stainless steel castings can be used in non-corrosive environments or corrosive environments at temperatures up to 800°F (426°C).

Our 316 Stainless Steel Casting is made of high-quality stainless steel that contains molybdenum, nickel, and chromium. These elements make the steel highly resistant to corrosion and able to withstand harsh environments. The steel is also highly durable, making it suitable for various applications in different industries. We use an advanced casting process to create our 316 Stainless Steel Casting to ensure that they meet the highest standards of quality.

SS 304 Investment Casting is produced using state-of-the-art technology and is made of high-quality stainless steel. It is well suited for a wide range of applications in various industries, including aerospace, automotive, medical, industrial, and more.

SS 304 investment casting is the most common stainless steel casting grade, mainly due to its excellent corrosion resistance. It contains 16% to 24% chromium and up to 35% nickel, as well as small amounts of carbon and manganese. It is susceptible to corrosion from chloride solutions or saline environments such as the coast.

Lost Wax Precision Casting is a high-quality, cost-effective manufacturing process that produces intricate metal parts and components that meet industry standards and customer specifications.

As a lost wax precision casting part manufacturer in China, we specialize in lost wax precision casting, producing high-quality products that are durable, reliable, and cost-effective.

Steel casting valves are an essential component in various industries, including oil and gas, pharmaceuticals, chemical, and petrochemical industries. A steel casting valve is a valve made from carbon and steel alloys that can withstand high temperatures and pressures. Steel Casting Valves are made by melting steel and then molding it into a desired shape.

Lost Wax Investment Casting, also known as investment casting or precision casting, is a manufacturing process that creates a mold using a wax pattern of an item to be cast. The wax pattern is then coated with a refractory ceramic material and heated to remove the wax, leaving a hollow mold. Molten metal is then poured into the mold, filling the cavity and taking the shape of the original wax pattern as it cools and solidifies.

Investment Cast 316 Stainless Steel:

Investment Cast 316 Stainless Steel is known for its superior corrosion resistance, making it ideal for any application that is too corrosive for the use of 304 ss. The reason for the higher corrosion resistance is due to the higher molybdenum and nickel content of the 316 casting grade.

Silica Sol Precision Casting Parts Manufacturers Questions Guide:

FAQ

Q: How High Precision Stainless Steel Impellers are produced?

Patterns Making: The so-called pattern making is to first make a wax mold with the appearance and shape exactly the same as the stainless steel impeller we need, but with a slightly larger size. Here, considering the shrinkage of the stainless steel and the pattern material, the size of the wax pattern is slightly larger than the size of cast impeller. The wax pattern is formed by pressing molten wax material into the tooling for solidification.

Shell Forming: It is the process that coating the wax pattern with a layer of fire-resistant paint, and then to be sprinkled with sand, so after a period of hardening, the surface will form a layer of fire-resistant thin shell.

Dewaxing: In this process, the shell will be put into the heating oven. Under high temperature, the wax material in the shell will be melted fully. Then, dry the shell to prepare for casting.

Pouring: Pouring liquid stainless steel into the shell, and waiting for solidification under room temperature.

Post Treatment: After cooling, knock the shell and cut the sprue gate by grinding machine to achieve net shape impeller castings. Then, shot blasting to move mill scales and smooth the surface.

Q: Why Stainless Steel Casting for Impeller?

Q: what is 316 Stainless Steel Casting?

316 stainless steel is the second most common material for stainless steel casting and is ideal for casting components, especially for marine applications. It is resistant to chemical corrosion and marine environments because of the addition of molybdenum. 316 stainless steel castings are sometimes known as "marine-grade" steel and are frequently used for maritime hardware. It is used in laboratories, coastal construction, and marine fittings in addition to the traditional applications of 304 stainless steel.

Q: How are Lost Wax Precision Castings Made?

Q: What are the advantages of Steel Casting Valve?

Flexibility in design: Steel Casting Valves can be cast into any shape or size.

Cost-effective production: Casting is a cost-effective approach to valve manufacturing as it allows for large-scale production of items.

Less machining costs: Usingsteel casting valves means far less machining costs in comparison to forged valves.

Q: How Investment Cast 316 Stainless Steel is produced?

1.Create a wax pattern

2.Coat the wax pattern with a ceramic slurry to create a mold

3.Melt the wax out of the ceramic mold

4.Pour molten metal into the cavity

5.Break or blast off the ceramic shell to create a metal casting

6.Clean, polish, and inspect the finished stainless steel part for quality

Q: Why Choose Silica Sol Casting Parts Ss316 Stainless Steel?

Q: What are the advantages of Stainless Steel Silica Sol Casting?

Ability to produce complex components: Stainless steel silica sol casting can manufacture complicated components with sophisticated geometries and elaborate forms. This is owing to the high level of control over the casting process, which permits the fabrication of complex parts with high precision and detail.

Repeatability: Stainless steel silica sol casting gives repeatable outcomes, making it an excellent method for mass-producing components.

Environmentally friendly: Stainless steel silica sol casting is environmentally beneficial because it does not generate toxic byproducts. This makes it a more sustainable option for component production.

High precision and accuracy: The silica sol solution used in the casting process gives a high level of detail and surface quality, resulting in a very accurate finished product. This makes stainless steel silica sol casting perfect for manufacturing components with precise geometries and tight tolerances.

High mechanical properties: High mechanical properties: Precise control over the casting process permits consistent and uniform cooling and solidification of the metal, resulting in components with high strength and tensile strength. This enables the use of stainless steel silica sol casting in demanding applications.

Versatility: Stainless steel silica sol casting can create components from various materials, such as stainless steel, titanium, and nickel-based alloys.

Cost-effective: Stainless steel silica sol casting is a cost-effective technology for generating high-quality components since it requires minimal post-casting processing and has a low scrap rate.

Q: What are the characteristics of 304 Stainless Steel Casting?

Corrosion Resistance: 304 Stainless Steel Casting is known for its excellent corrosion resistance in a wide range of environments, including those with exposure to chemicals, saltwater, and acidic solutions.

Strength and Durability: It offers good strength and durability, making it suitable for a wide range of applications, from kitchen appliances to automotive parts.

Weldability: 304 Stainless Steel Casting is easily weldable, which makes it a popular choice for fabrication processes.

Cost-Effective: It is relatively more affordable than some other stainless steel grades, making it a cost-effective choice for many projects.

Q: What are the advantages of 316 Stainless Steel Casting?

Enhanced Corrosion Resistance: 316 Stainless Steel Casting provides superior corrosion resistance, especially in marine and chloride-rich environments.

High Temperature Resistance: It can withstand higher temperatures than 304 stainless steel, making it suitable for high-temperature applications.

Excellent Weldability: 316 Stainless Steel Casting is also easily weldable, maintaining its corrosion resistance after welding.

Hygienic Properties: Similar to 304 stainless steel, 316 is also hygienic and often used in food and pharmaceutical industries.

Q: What are the applications of 304 Stainless Steel Casting?

Food Industry: 304 Stainless Steel Casting is often used in food processing equipment and kitchen appliances due to its corrosion resistance and hygienic properties.

Architectural Applications: It is used in architectural elements like handrails, balustrades, and decorative panels due to its aesthetic appeal and corrosion resistance.

Automotive Industry: Many automotive components, such as exhaust systems and trim, are made from 304 Stainless Steel Casting due to its durability and resistance to road salts.

Chemical and Petrochemical Industries: 304 Stainless Steel Casting is used in equipment that handles various chemicals and corrosive substances.

Q: What are the applications of 316 Stainless Steel Casting?

Marine and Coastal Applications: Due to its exceptional resistance to saltwater and harsh marine conditions, 316 Stainless Steel Casting is widely used in boat fittings, marine hardware, and coastal construction.

Chemical and Pharmaceutical Industries: 316 Stainless Steel Casting is preferred in applications where corrosion resistance and chemical compatibility are crucial.

Medical Equipment: Surgical instruments and medical devices often use 316 stainless steel for its biocompatibility and corrosion resistance.

Aerospace Industry: Aerospace components exposed to harsh environments can benefit from the corrosion resistance of 316 stainless steel.

Q: what is Lost Wax Investment Casting?

Lost Wax Investment Casting can be used to create objects with fine details, thin walls, and close tolerances. It can be used to cast objects in a variety of metals, including: gold, silver, brass, copper, bronze, and aluminum.

Q: what is ss 304 Investment Casting?

ss 304 Investment Casting is widely used in the food industry and has the reputation for being the standard for cleanliness and corrosion resistance. It is also soft and much easier to straighten than 316 or 17-4.

Q: what is Silica Sol Precision Casting Parts?

China Hai Xin Nuo - Your professional Silica Sol Precision Casting Parts Supplier

We're well-known as one of the leading Precision Casting Parts manufacturers and suppliers in China. The products we can provide you with include: High Precision Stainless Steel Impellers, Silica Sol Casting Parts SS316 Stainless Steel, Silica Sol Precision Casting Parts, Stainless Steel Silica Sol Casting, 304 Stainless Steel Casting, ss 304 Investment Casting, Steel Casting Valve, Lost Wax Investment Casting, Investment Cast 316 Stainless Steel, etc.

If you're going to buy custom made Precision Casting Parts at competitive price, welcome to get more company information from our factory.

Hot Tags: silica sol precision casting parts, China silica sol precision casting parts manufacturers, suppliers, factory