Yo, what's up! I'm a supplier in the stainless steel casting biz, and today I wanna talk about one of the key properties of stainless steel castings: elongation.

So, what the heck is elongation when it comes to stainless steel castings? Elongation is basically a measure of how much a material can stretch before it breaks. In the world of stainless steel castings, it's super important 'cause it tells us a lot about the material's ductility and its ability to handle stress without failing.

Let's break it down a bit more. When we're talking about elongation, we're usually looking at it as a percentage. For example, if a stainless steel casting has an elongation of 20%, it means that when it's pulled under a certain load, it can stretch to 120% of its original length before it snaps.

Why does this matter? Well, think about the applications of stainless steel castings. They're used in all sorts of industries, from automotive to aerospace, and even in everyday stuff like kitchen appliances. In these applications, the castings often have to withstand a fair amount of force or deformation. If a casting doesn't have enough elongation, it might crack or break under stress, which can lead to some serious problems.

For instance, in the automotive industry, stainless steel castings are used in engine components. These parts need to be able to handle the high temperatures and pressures inside the engine. If the castings have low elongation, they might not be able to expand and contract properly with the changes in temperature and pressure, leading to premature failure.

Now, the elongation of stainless steel castings can be affected by a bunch of factors. One of the main ones is the chemical composition of the stainless steel. Different grades of stainless steel have different amounts of elements like chromium, nickel, and carbon, and these elements can have a big impact on the material's properties, including elongation.

For example, austenitic stainless steels, which are known for their good corrosion resistance, usually have higher elongation compared to ferritic stainless steels. This is because the austenitic structure is more ductile, allowing the material to stretch more before breaking.

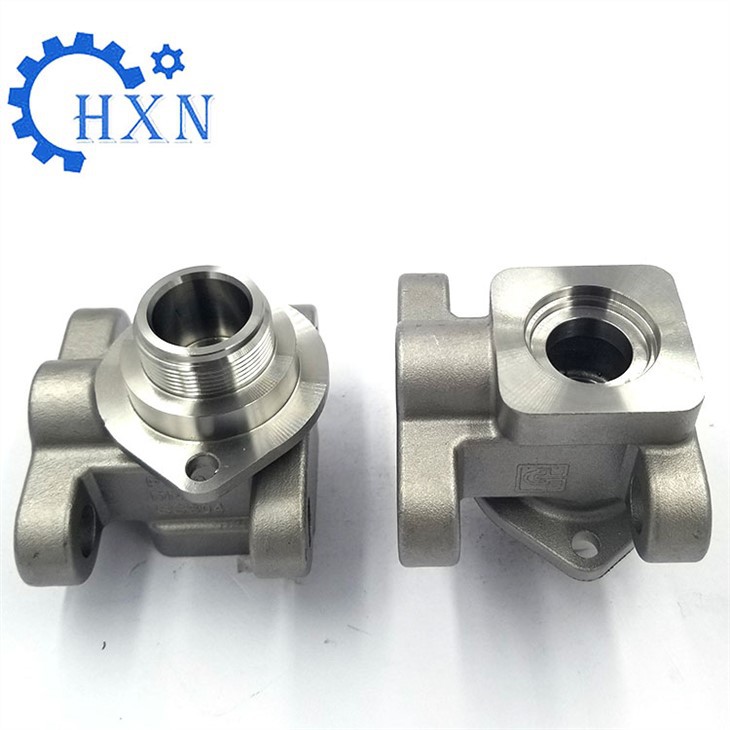

Another factor that can affect elongation is the casting process. The way the casting is made can influence its internal structure and, in turn, its mechanical properties. For example, Silica Sol Precision Casting Parts use a very precise casting method that can produce high-quality castings with good mechanical properties, including elongation. This process involves creating a ceramic shell around a wax pattern and then pouring the molten stainless steel into the shell. The result is a casting with a fine-grained structure, which can enhance its elongation.

Similarly, Shell Mold Casting For Stainless Steel Products is another method that can affect the elongation of the castings. This process uses a shell mold made of refractory materials to shape the casting. The quality of the shell mold and the pouring process can impact the internal structure of the casting and its ability to stretch.

Silica Sol Precision Casting is also known for producing castings with good elongation. This method offers a high level of precision and can control the microstructure of the casting, which is crucial for achieving the desired mechanical properties.

When it comes to testing the elongation of stainless steel castings, there are standard procedures in place. Usually, a sample of the casting is taken and tested using a tensile testing machine. The machine applies a gradually increasing load to the sample until it breaks, and the elongation is measured as the increase in length of the sample compared to its original length.

In the industry, we always aim to produce stainless steel castings with the right balance of properties, including elongation. We need to make sure that the castings can meet the requirements of our customers, whether it's for a high-performance aerospace component or a simple household item.

If you're in the market for stainless steel castings, it's important to consider the elongation property. You want to make sure that the castings you're buying can withstand the stresses and strains they'll be exposed to in your application.

As a supplier, I've seen firsthand how important it is to get the elongation right. We work hard to control the factors that affect elongation, from the chemical composition of the steel to the casting process. We use advanced technology and quality control measures to ensure that our castings meet the highest standards.

So, if you're looking for high-quality stainless steel castings with the right elongation, don't hesitate to reach out. We can provide you with castings that are tailored to your specific needs and requirements. Whether you need Silica Sol Precision Casting Parts, Shell Mold Casting For Stainless Steel Products, or any other type of stainless steel casting, we've got you covered.

Let's have a chat about your project and see how we can help you get the best stainless steel castings on the market. Contact us today to start the discussion!

References:

- "Metallurgy of Stainless Steels" by George E. Totten

- "Foundry Technology" by David Croll