Accurately measuring the dimensions of CNC machining components is a critical aspect of the manufacturing process. As a supplier of CNC machining components, ensuring the precision of these measurements is not only a matter of quality control but also a key factor in meeting the diverse needs of our customers. In this blog, I will share some effective methods and considerations for measuring the dimensions of CNC machining components accurately.

The Importance of Accurate Dimension Measurement

In the world of CNC machining, even the slightest deviation from the specified dimensions can lead to significant issues. Components that do not meet the required tolerances may not fit properly into the final assembly, leading to performance problems, increased wear and tear, and even safety hazards. Moreover, in industries such as aerospace, automotive, and medical, where precision is of utmost importance, accurate dimension measurement is non - negotiable.

As a supplier, we understand that our customers rely on us to provide high - quality components that meet their exact specifications. By ensuring accurate dimension measurement, we can build trust with our customers, enhance our reputation in the market, and ultimately contribute to the success of their projects.

Tools for Dimension Measurement

Vernier Calipers

Vernier calipers are one of the most commonly used tools for measuring the dimensions of CNC machining components. They can measure both internal and external dimensions, as well as depths. Vernier calipers offer a relatively high level of accuracy, typically up to 0.02 mm or 0.001 inches. They are easy to use and are suitable for measuring a wide range of component sizes.

Micrometers

Micrometers are another essential tool for precision measurement. They are capable of providing even higher accuracy than vernier calipers, often up to 0.001 mm or 0.0001 inches. Micrometers come in different types, such as outside micrometers for measuring external diameters, inside micrometers for internal diameters, and depth micrometers for measuring depths. They are particularly useful for measuring small and precise components.

Coordinate Measuring Machines (CMMs)

CMMs are advanced measuring devices that use a probe to measure the coordinates of points on the surface of a component. They can measure complex geometries and provide highly accurate dimensional data. CMMs are controlled by computer software, which allows for automated measurement and data analysis. They are widely used in industries where high - precision measurement is required, such as aerospace and automotive manufacturing.

Optical Measuring Systems

Optical measuring systems, such as vision measuring machines and laser scanners, use light to measure the dimensions of components. Vision measuring machines use cameras to capture images of the component and then analyze the images to determine the dimensions. Laser scanners, on the other hand, use lasers to scan the surface of the component and create a 3D model. Optical measuring systems are fast, non - contact, and can measure complex shapes with high accuracy.

Measurement Procedures

Pre - measurement Preparation

Before starting the measurement, it is important to ensure that the measuring tools are clean, calibrated, and in good working condition. Calibration is crucial to ensure the accuracy of the measurement results. Tools should be calibrated regularly according to the manufacturer's recommendations.

The component to be measured should also be cleaned to remove any dirt, debris, or coolant that may affect the measurement. It is important to handle the component carefully to avoid any damage or deformation that could lead to inaccurate measurements.

Measuring Multiple Points

When measuring a component, it is often necessary to measure multiple points to ensure the accuracy of the dimensions. For example, when measuring the diameter of a cylindrical component, it is recommended to measure at several different locations along the length of the cylinder to check for any variations. This is especially important for components with complex geometries or those that are prone to deformation.

Taking Average Values

In some cases, it may be necessary to take multiple measurements at the same point and then calculate the average value. This can help to reduce the measurement error caused by factors such as tool wear, operator error, or environmental conditions.

Using Statistical Process Control (SPC)

SPC is a method of monitoring and controlling the manufacturing process to ensure that the components produced meet the required quality standards. By collecting and analyzing measurement data over time, SPC can help to identify trends and variations in the manufacturing process. This allows for timely adjustments to be made to the process to ensure the consistency and accuracy of the component dimensions.

Considerations for Different Machining Processes

5 Axis Machined Parts

5 Axis Machined Parts offer greater flexibility and the ability to produce complex geometries compared to traditional machining processes. However, measuring the dimensions of 5 axis machined parts can be more challenging due to their complex shapes. Specialized measuring tools and techniques may be required to accurately measure these parts. For example, CMMs with advanced probing systems can be used to measure the complex surfaces of 5 axis machined parts.

CNC Milling Machining Services

CNC Milling Machining Services are widely used in the manufacturing of various components. When measuring the dimensions of milled parts, it is important to consider the effects of factors such as tool wear, cutting forces, and workpiece material. These factors can cause variations in the dimensions of the milled parts. For example, tool wear can lead to a decrease in the cutting diameter, resulting in undersized components. Regular tool inspection and replacement are necessary to ensure the accuracy of the milled parts.

Turn - milling Compound Machining

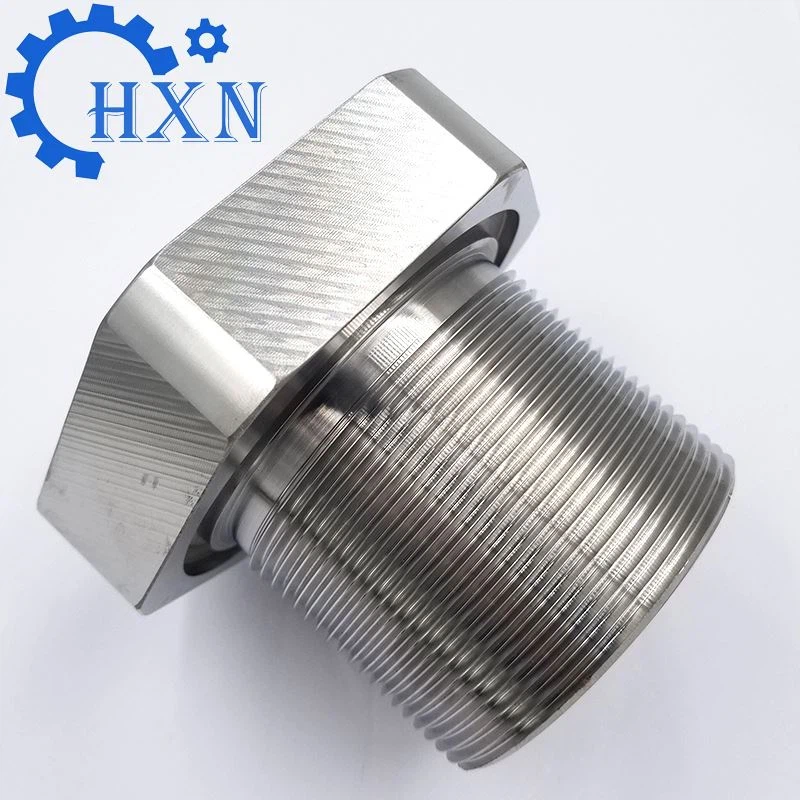

Turn - milling Compound Machining combines the advantages of turning and milling processes, allowing for the production of complex components in a single setup. Measuring the dimensions of turn - milled parts requires careful consideration of the characteristics of both turning and milling processes. For example, the roundness and cylindricity of the turned features need to be measured accurately, while the flatness and surface finish of the milled features also need to be checked.

Quality Assurance and Traceability

In addition to accurate measurement, quality assurance and traceability are also important aspects of the manufacturing process. We implement a comprehensive quality management system to ensure that all our CNC machining components meet the highest quality standards. This includes in - process inspection, final inspection, and documentation of the measurement results.

By maintaining detailed records of the measurement data, we can provide traceability for each component. This allows us to track the production history of the component, identify any potential quality issues, and provide our customers with the necessary documentation for their quality control requirements.

Conclusion

Accurately measuring the dimensions of CNC machining components is crucial for ensuring the quality and performance of the final products. As a supplier of CNC machining components, we are committed to using the latest measuring tools and techniques to provide our customers with high - precision components. By following the proper measurement procedures, considering the characteristics of different machining processes, and implementing a comprehensive quality management system, we can meet the diverse needs of our customers and contribute to the success of their projects.

If you are in need of high - quality CNC machining components, we invite you to contact us for procurement and further discussions. Our team of experts is ready to provide you with professional solutions and excellent service.

References

- ASME Y14.5 - 2018, "Dimensioning and Tolerancing"

- ISO 10360 - 1:2019, "Geometrical product specifications (GPS) — Acceptance and reverification tests for coordinate measuring machines (CMM) — Part 1: Terminology and general measurement principles"

- Montgomery, D. C. (2013). "Introduction to Statistical Quality Control". Wiley.