Founded in 2008, Qingdao HaiXinNuo Machinery is a professional machinery company in the coastal city of Qingdao. HXN has precision casting production line and more than 60 kinds of machining equipments. Such as CNC lathes, Swiss CNC Lathe machine, 4 Axis machining centers, 5 Axis machining centers, wire cutting machines, milling machines, drilling machines and other equipments at state-of-the-art. Our business is involved in the manufacturing of machinery parts, standard parts, customized parts, welding, fixture as well as the design and manufacturing of non-standard equipment parts. We specialize in manufacturing non-standard customized parts, the main processes are precision casting and CNC machining. Our product includes all materials, carbon steel, alloy steel, stainless steel, brass, and aluminum.

Why Choose Us

Our equipment

HXN has precision casting production line and more than 60 kinds of machining equipments. Such as CNC lathes, Swiss CNC Lathe machine, 4 Axis machining centers, 5 Axis machining centers, wire cutting machines, milling machines, drilling machines and other equipments at state-of-the-art.

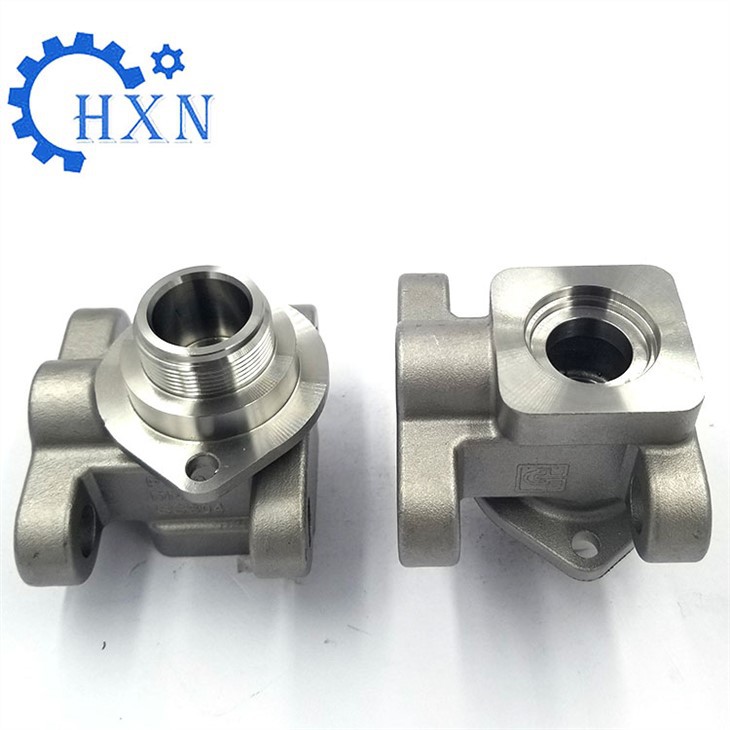

Our product

We specialize in manufacturing non-standard customized parts, the main processes are precision casting and CNC machining. Our product includes all materials, carbon steel, alloy steel, stainless steel, brass, and aluminum.

Our certificate

We always feel that all success of our company is directly related to the quality of the products we offer. They meet the highest quality requirements as stipulated in ISO9001, ISO14000:14001 SGS guidelines, and our stringent quality control system.

Production market

We have customers from both the domestic market and the oversea market. Sales managers can speak fluent English for good communication. The total value of output is up to 5 million USD, exported to more than 20 countries. HXN products are widely used in the flow control industry and various kinds of equipment.

Related Product

Silica Sol Precision Casting Parts

The lost wax casting process produces near-net-shape precision metal parts that often require little to no additional machining. The resulting finish is also much better than what is achievable through most other processes. And, the strength and durability of cast metal parts makes them ideal for high wear applications requiring millions of cycles.s

The lost wax casting process produces near-net-shape precision metal parts that often require little to no additional machining. The resulting finish is also much better than what is achievable through most other processes. And, the strength and durability of cast metal parts makes them ideal for high wear applications requiring millions of cycles.

Investment Cast 316 Stainless Steel

HXN (Qingdao HaiXinNuo Machinery Co., Ltd) can produce high-quality, high-precision steel investment casting parts for customers as our goal and has always been a struggle.

Stainless Steel Silica Sol Casting

The silica sol casting process produces near-net-shape precision metal parts that often require little to no additional machining. The resulting finish is also much better than what is achievable through most other processes. And, the strength and durability of cast metal parts make them ideal for high wear applications requiring millions of cycles.

We are a global leader in the field of investment casting. Investment casting is a metal forming process in which a ceramic mold is usually made from a wax mold wrapped around a ceramic shell. The products we can provide you with include: High Precision Stainless Steel Impellers, Silica Sol Casting Parts SS316 Stainless Steel, 304 Stainless Steel Casting, ss 304 Investment Casting, Steel Casting Valve, Investment Cast 316 Stainless Steel, etc.

We are a global leader in the field of investment casting. Investment casting is a metal forming process in which a ceramic mold is usually made from a wax mold wrapped around a ceramic shell.

Shell Mold Casting For Stainless Steel Products

This large casting product is made from stainless steel (SS316), which weighs about 200kg. It underwent shell mold casting, followed by CNC machining, and CMM inspection, to get the final product.

Shell Mold Casting Stainless Steel Impellers

This large impeller is constructed from stainless steel (SS316), which weighs about 500kg. It underwent shell mold casting, followed by CNC machining, inspection, and dynamic balancing to achieve the final product.

High Precision Stainless Steel Impellers

The precision casting and machining of small stainless steel impellers involve several key considerations to ensure that the final product meets the required specifications and quality standards.

What Is Lost Wax Investment Casting

Lost-wax casting also called investment casting, precision casting, or cire perdue is the process by which a duplicate sculpture (often a metal, such as silver, gold, brass, or bronze) is cast from an original sculpture. Intricate works can be achieved by this method. lost wax investment casting, as it' s sometimes known as investment casting, is a process in which metal castings are designed and produced, often to near net shape capabilities. The term 'lost wax' is named becaused the wax models have to be melted to complete the casting process, leaving a hollow shell to pour liquid metal. Once solification, the cast piece is formed.

Advantages of Lost Wax Investment Casting

Smooth finishes

Since the molds from lost wax investment casting are made from ceramics, produced products are ready to ship or attach after being cast. The roughness average (ra) of a lost wax cast part averages around 125, which is the average of the peaks and valleys on the finished surface.

Production turnaround

One of the critical factors in modern manufacturing is turnaround times since products have to be mass produced in a short time frame. Since lost wax cast parts do not require finishing, parts can be rapidly produced and shipped, which is further assisted by the reduction in handling and labor.

Close tolerances

The biggest advantage of lost wax investment casting is the tight and accurate tolerances that have a standard of ± 0.005. Cad computer designs are accurately and precisely recreated to exactly fit the final application.

Variety of metals

There are very few limitations to the types and kinds of metals that can be used in lost wax investment casting. The types of metals include bronze, stainless steel, alloy steel, iron, aluminum, and copper, to name a few. The wide selection gives engineers a varied array of choices when designing parts. It also makes the process adaptable to any industry.

Wax model spraying & Tree building

The mould is filled with liquid wax. After the wax has been cooled down, ejectors in the mould push the wax model out. A wax model has now been sprayed which is identical to the final casting. These wax models are glued onto a so-called wax tree with a casting funnel on top, into which steel is poured in a later stage off the process.

Rinsing the wax trees

After the wax models have been glued onto a wax tree, they are rinsed. Any possible contaminations on the surface are removed to ensure a successful attachment of the ceramic onto the wax tree.

Building ceramic layers

After rinsing the wax tree, the tree is given a fireproof ceramic shell. This shell is constructed after repeatedly submerging the tree (up to 7 or 9 times) in a slurry and sprinkle it with ceramic sand. The ceramic layers are then hardened in a drying chamber where they are exposed to air.

Autoclave

After the layers have been formed and dried, the wax is melted out of the ceramic tree by using steam (120°C) in an autoclave. This is why it is called "lost wax casting". The majority of the molten wax can be regenerated and is reusable.

Sintering

The ceramic tree is then baked (stoked) at high temperatures of around 1100°C and reaches its final strength through the sintering process. Any wax remains are burned out during this process.

Casting

The desired steel alloy is melted in a large furnace of 800kg and brought to cast temperatures. The ceramic tree is, at the same time, heated in a oven to prevent thermal shocks during the pouring process. After the tree has been heated, it is removed from the oven by a robotic arm and filled up with a steel alloy by use of counter gravity. When the trees have been poured, they are placed on a cooling conveyor where they are cooled down. (with nitrogen).

Finishing

The trees are then removed from their ceramic shell, by using a fully-automatic hammer to break the shell. This removes the majority of the ceramic. The next step is to cut the products from the trees by sawing or vibrating. The steel leftovers will be sorted based on alloy and can be melted again during the next casting session.

Blasting, grinding and visual inspection

The finishing department removes the last pieces of ceramic by means of steel, sand and/or water blasting. The ingate which remained after the sawing process, is grinded from the casting. To grind the product properly, a grinding fixture is often applied.

Machining and heat- and surface treatment

We have the capabilities to machine castings in house, such as drilling holes, tapping threads and turning & milling activities. This enable to deliver a completely machined component that is ready-to-install.

Metals of Lost Wax Investment Casting

Stainless steel

The main alloys of stainless steel are chromium, nickel, and molybdenum, which determine the grain and mechanical properties of the casting. How the alloys are combined decides how the casting will be able to endure heat and resist corrosion. Since stainless steel is 10% chromium, it is resistant to liquid corrosive conditions and oxidation.

Steel

Carbon, low alloy, and tool steels are used in the aerospace, agricultural, medical, and firearm industries, to name a few. Steel is chosen for lost wax casting because it is economical, available in several grades, and can be heat treated to adjust its ductility.

Ductile Iron

Ductile iron castings have exceptional surface hardness, elasticity modulus, corrosion resistance, and a strong strength to weight ratio. The greatest benefit of ductile iron is that it is cost effective and offers a wide range of design freedom.

Beryllium copper

Beryllium copper, after heat treatment, has exceptional thermal and electrical conductivity with hardness that is greater than steel and thermal conductivity greater than aluminum. Castings made from beryllium copper have good ductility, are easily welded, and can be easily machined. Copper that is made with 2.0% to 2.5% beryllium has excellent wear, toughness, and is anti-galling.

Aluminum

Aluminum is an ideal metal for lost wax casting due to its machinability and corrosion resistance. When it is alloyed with other metals and heat treated, it develops exceptional strength that is comparable to low carbon steel. The fluid nature of aluminum alloys allows for parts to have thin walls.

Cobalt

Cobalt is naturally resistant to oxidation with a hard and lustrous finish. It is protected from oxidation by a passivating oxide film. Cobalt is found in nature combined with other alloys and is separated using a smelting process. The corrosion, heat, and wear resistance of cobalt makes it ideal for lost wax casting and is used to produce parts for aerospace, the automotive industry, and for military use. It can be found in orthopedic implants for its wear resistance.

Brass

Brass, a copper alloy known as red or yellow brass, lost wax castings are used for plumbing fixtures and door hardware. The main characteristic of brass is its appearance as well as its finishing and polishing qualities. The one drawback to the use of brass is its lead content, which has restricted its use.

Bronze

The nature and quality of bronze depends on the alloys with which it is combined. The added elements of bronze are what enhances its performance and quality. Tin increases its strength, while lead decreases its strength but increases its lubricity. To create corrosion resistance and increase strength, manganese and aluminum can be added.

Nickel

Nickel contains nickel, chromium, and molybdenum and has exceptional strength as well as resistance to heat, wear, and corrosion. It is chosen as a casting metal because it can be easily welded and fabricated with resistance to cracking and corrosion. Nickel alloy castings are used in applications where there is extreme heat and corrosion, such as aerospace, marine environments, and chemical factories.

Applications of Lost Wax Investment Casting

Jewelry production

This is one of the earliest and still prevalent uses of lost wax casting, where it allows for the creation of intricate designs and patterns in precious metals.

Dentistry

Lost wax casting is employed to create detailed dental fixtures and structures, leveraging its ability to produce small, complex shapes with a high degree of accuracy.

Art

Artists often use lost wax casting for sculptures and other art forms, benefiting from the technique's capacity to capture fine details and the artist's original intent.

Aerospace industry

The aerospace sector uses lost wax casting to manufacture critical components like turbine blades and engine parts. The process is ideal for producing parts that must meet stringent standards for precision and reliability.

Medical devices

In the medical field, lost wax casting is applied in manufacturing orthopedic implants, such as screws, which require high precision and compatibility with human tissue.

Engineering and manufacturing

The industrial form of lost wax casting, investment casting, is commonly used to create precision metal parts for various engineering and manufacturing applications, demonstrating the process's adaptability to produce components with complex geometries and tight tolerances. These applications highlight the significance of lost wax casting in modern-day production across a range of fields, from artistry to aerospace engineering, due to its unique ability to produce precise, high-quality components.

When wax is used to make a shape, investment casting is also called "lost wax investment casting". Investment casting usually refers to the casting scheme in which the shape is made of fusible materials, and the shape surface is coated with a number of layers of refractory material to make a shell, and then the shape is melted and discharged from the shell, so as to obtain the casting without parting surface, and the sand can be filled after high temperature roasting. Because the shape is widely made of wax material, investment casting is often called "lost wax investment casting".

The types of alloys that can be produced by investment casting are carbon steel, alloy steel, heat-resistant alloy, stainless steel, precision alloy, permanent magnet alloy, bearing alloy, copper alloy, aluminum alloy, titanium alloy and ductile iron, etc. Its limitations: casting size can not be too large process complex casting cooling speed is slow. Investment casting among all blank forming methods, the process is complex and the casting cost is high, but if the product is chosen properly, the parts are designed reasonably, and the high casting cost is compensated by the reduction of cutting, assembly and saving of metal materials, then investment casting has good economy.

Method of Cleaning Castings in Lost Wax Investment Casting

Method of cleaning castings in lost wax investment casting process --There are three kinds of casting cleaning methods in lost wax investment casting process : mechanical method, physical method and chemical method.Mechanical method is the use of a variety of manual and motor tools or different types of mechanical equipment produced by the pressure, impact, shear, grinding and other forces acting on the casting, in order to achieve the purpose of cleaning.The physical method is to clean up the casting using arc, plasma, laser, ultrasonic wave and shock wave.

The chemical method is sticky sand using hydrofluoric acid dissolved silica and salt solution electrolysis, remove small castings; also has the characteristics of cutting and cutting by oxidation of intense oxidation of some metals at high temperature. In addition to the core and surface cleaning is divided into dry and wet method. Two kinds of dry cleaning method to clean the castings by mechanical devices. The device is simple, high production efficiency, has great adaptability and can effectively clean the surface of the core in addition to the advantages of different types of castings.The disadvantage is the operation of equipment, often flying dust and noise pollution of the environment. No wet cleaning dust, but by using water as medium, the casting surface is easy to rust. To produce a large number of sewage and cement with sand in the work process, bring the sand and water regeneration and sludge treatment and other issues.

Dry and wet cleaning are commonly used in production:drump cleaning.The casting and ferroplasm together into a circular cylinder, when the drum rotates, rely on iron castings, star, waste sand between the impact and friction of the scavenging effect of casting sand and grinding, the surface of the casting, but also can remove part of burr. Medium and small sized castings of this kind of equipment for cleaning the shape is simple, with thick walls.

The use of high-speed movement of steel, iron balls, abrasive flow impact strength to clear the core, sticky sand, polished surface of casting .The high pressure water is injected into the treated castings from the spray nozzle through the pipe, and the core and the casting sand are removed by the kinetic energy and scouring action of the flow.Hydraulic cleaning is usually made consisting of steel and steel exposure to clean up the room is arranged at the bottom of the rotary table, the spray gun is installed on the side wall can move up and down and turn any part of the high-pressure water flow at the bottom surface of the casting except.Sometimes, in order to improve the efficiency of removing sand on the surface of castings, the abrasive sand such as quartz sand is introduced into the proper position of the spray gun to obtain high speed water sand flow.

Our factory

Founded in 2008, Qingdao HaiXinNuo Machinery is a professional machinery company in the coastal city of Qingdao. HXN has precision casting production line and more than 60 kinds of machining equipments. Such as CNC lathes, Swiss CNC Lathe machine, 4 Axis machining centers, 5 Axis machining centers, wire cutting machines, milling machines, drilling machines and other equipments at state-of-the-art. Our business is involved in the manufacturing of machinery parts, standard parts, customized parts, welding, fixture as well as the design and manufacturing of non-standard equipment parts. We specialize in manufacturing non-standard customized parts, the main processes are precision casting and CNC machining. Our product includes all materials, carbon steel, alloy steel, stainless steel, brass, and aluminum. We always feel that all success of our company is directly related to the quality of the products we offer. They meet the highest quality requirements as stipulated in ISO9001, ISO14000:14001 SGS guidelines, and our stringent quality control system. We have customers from both the domestic market and the oversea market. Sales managers can speak fluent English for good communication.

Certificate

FAQ

Hot Tags: lost wax investment casting, China lost wax investment casting manufacturers, suppliers, factory, precision casting supplier, precision die casting, Automatic Lathe Machining, siemens cnc, 3018 pro, api 600 globe valve