As an OEM CNC milling parts supplier, I often get asked if our parts are suitable for use in cleanroom environments. It's a valid question, considering the strict requirements and high - precision needs of cleanroom operations. In this blog, I'll share my insights on this topic.

Understanding Cleanroom Environments

First, let's talk about what cleanroom environments are. Cleanrooms are specialized spaces where the concentration of airborne particles is controlled. They're used in industries like semiconductor manufacturing, pharmaceuticals, and biotechnology. In these industries, even the tiniest particle can cause significant problems, such as product contamination or equipment malfunction.

Cleanrooms are classified based on the number of particles per cubic meter at a specific particle size. For example, a Class 1 cleanroom allows no more than one particle of 0.1 micrometers or larger per cubic meter of air. That's an incredibly clean environment!

The Characteristics of OEM CNC Milling Parts

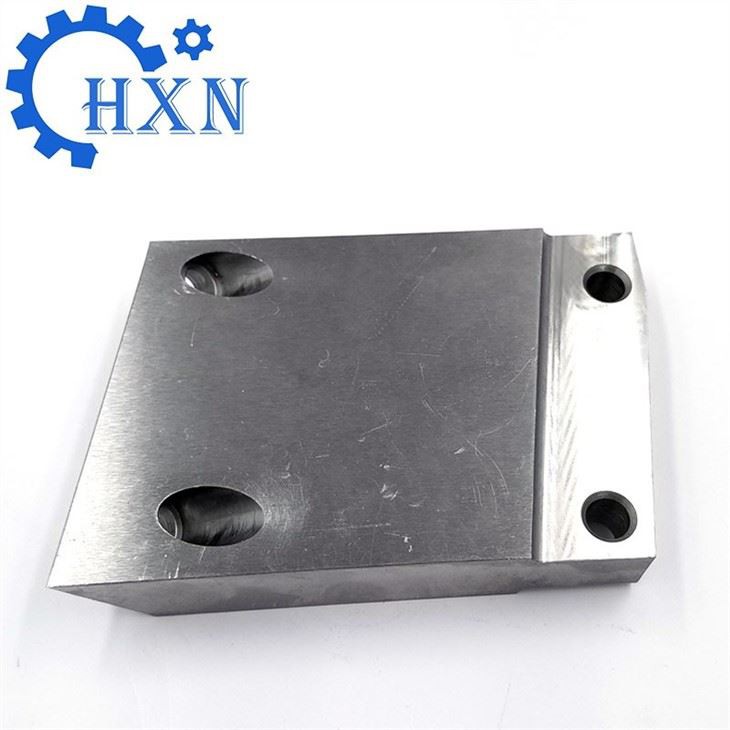

OEM CNC milling parts are manufactured using computer - numerical - control (CNC) milling machines. These machines use pre - programmed computer software to control the movement of cutting tools and machinery. The result is highly precise parts with tight tolerances, which is great for many applications.

One of the advantages of CNC milling is the ability to produce complex shapes and geometries. Whether it's a simple bracket or a highly intricate component, CNC milling can handle it. Also, CNC milling can be used with a wide range of materials, including metals like aluminum, steel, and titanium, as well as plastics and composites.

Suitability of OEM CNC Milling Parts for Cleanroom Environments

Now, let's get to the main question: are OEM CNC milling parts suitable for cleanroom environments? The answer is: it depends.

1. Material Selection

The choice of material is crucial. Some materials are more prone to particle shedding than others. For example, certain plastics may release small particles over time due to wear and tear. On the other hand, metals like stainless steel are generally more stable and less likely to shed particles. As a supplier, we carefully select materials based on the cleanroom requirements. For high - end cleanroom applications, we often recommend stainless steel or other low - particle - shedding materials.

2. Manufacturing Process

The manufacturing process itself can introduce contaminants. During CNC milling, cutting fluids are often used to cool the cutting tool and remove chips. If these fluids are not properly managed, they can leave residues on the parts. To address this, we use clean manufacturing processes. We have strict procedures for cleaning the parts after machining, including ultrasonic cleaning and passivation for metal parts. This helps to remove any residual contaminants and ensure the parts meet the cleanroom standards.

3. Surface Finish

The surface finish of the parts also matters. A rough surface can trap particles, while a smooth surface is less likely to do so. Our CNC milling machines are capable of achieving very smooth surface finishes. We can also perform additional finishing operations, such as polishing, to further improve the surface quality of the parts.

4. Packaging and Handling

Once the parts are manufactured and cleaned, proper packaging and handling are essential. We use cleanroom - compatible packaging materials, such as anti - static bags and sealed containers, to prevent contamination during transportation and storage. Our staff is trained in cleanroom handling procedures to ensure that the parts remain clean from the factory to the customer's cleanroom.

Examples of Cleanroom - Ready OEM CNC Milling Parts

We've supplied many OEM CNC milling parts for cleanroom applications. For instance, we've made 4 Axis Machining Center Parts for semiconductor manufacturing equipment. These parts are made from high - grade stainless steel and undergo a rigorous cleaning and finishing process to meet the strict cleanroom standards.

Another example is our OEM CNC Milling Parts for pharmaceutical filling machines. These parts are designed to be highly precise and resistant to corrosion, which is important in a clean and sterile environment.

Large - Scale CNC Machining for Cleanroom Needs

For larger cleanroom equipment, we also offer Large CNC Machining Services. Whether it's a large frame or a custom - sized component, our CNC machines can handle the job. We have the capacity to manufacture large parts with the same level of precision and cleanliness as smaller ones.

Working with Us

If you're in need of OEM CNC milling parts for your cleanroom environment, we're here to help. We understand the unique requirements of cleanroom applications and have the expertise to produce parts that meet your standards.

We can work closely with you from the design phase to ensure that the parts are optimized for cleanroom use. Our team of engineers can provide advice on material selection, manufacturing processes, and finishing options. We also offer quality control services to guarantee that every part leaving our factory meets the highest quality standards.

Don't hesitate to reach out to us for a quote or to discuss your specific needs. Whether you're a small - scale biotech startup or a large semiconductor manufacturer, we have the capabilities to support your cleanroom operations.

References

- "Cleanroom Technology Handbook" by Peter A. Sullivan

- "CNC Machining: A Practical Guide" by John Doe