What is CNC Metal Machining Service

CNC Metal Machining Service refers to a precision manufacturing process that utilizes Computer Numerical Control (CNC) technology to remove material from metal workpieces. This process involves the use of advanced CNC machines, which are programmed with specific instructions to cut, drill, mill, or turn metal into the desired shape and size.

Why Choose Us

Our Equipment

HXN has precision casting production line and more than 60 kinds of machining equipments. Such as CNC lathes, Swiss CNC Lathe machine, 4 Axis machining centers, 5 Axis machining centers, wire cutting machines, milling machines, drilling machines and other equipments at state-of-the-art.

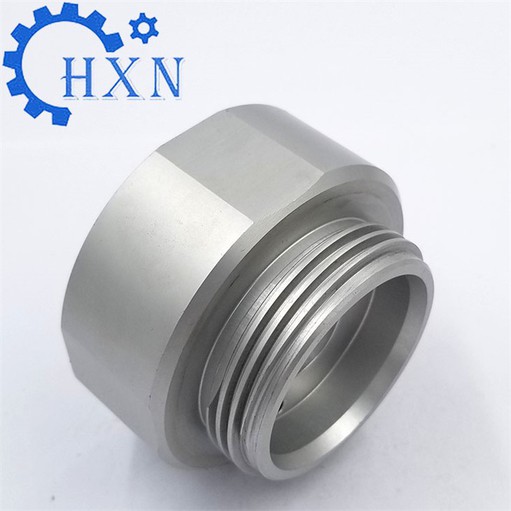

Our Product

We specialize in manufacturing non-standard customized parts, the main processes are precision casting and CNC machining. Our product includes all materials, carbon steel, alloy steel, stainless steel, brass, and aluminum.

Our Certificate

We always feel that all success of our company is directly related to the quality of the products we offer. They meet the highest quality requirements as stipulated in ISO9001, ISO14000:14001 SGS guidelines, and our stringent quality control system.

Production Market

We have customers from both the domestic market and the oversea market. Sales managers can speak fluent English for good communication. The total value of output is up to 5 million USD, exported to more than 20 countries. HXN products are widely used in the flow control industry and various kinds of equipment.

Advantages of CNC Metal Machining Service

Affordable price

One of the benefits of using this manufacturing method is that there is a minimum cost involved. Through CNC machining, they can have custom metal parts at a lower price.

Reduction in the production time

One of the essential benefits of CNC machining is the reduction in the production time. Spending more time on finding the right machined parts is counterproductive. Opting for CNC machining can take the specification and produce the unique OEM/ODM parts required. Using a strong material will also ensure the durability of the manufactured parts.

Accuracy

Another advantage of using CNC machining is the products and parts produced are incredibly accurate. Many industries require highly specific parts, and this method is the answer. Using CNC machining will also provide accurate parts consistently many times over using the same machine.

Tight tolerance

Many accurate pieces require high tolerance to manufacture, which is a critical component in many industries. Customers can take advantage of using CNC machines to produce these OEM and ODM parts, especially when a particular degree of tolerance is needed.

Applications of CNC Metal Machining Services

Aerospace Industry

The aerospace industry requires high-precision and high-quality metal parts for aircraft and spacecraft.

CNC metal machining is used to manufacture turbine blades, engine components, landing gear parts, and structural components with tight tolerances and complex geometries.

Automotive Industry

The automotive industry relies on CNC metal machining for the production of engine blocks, cylinder heads, transmission components, and other critical parts.

It allows for high-volume production with consistent quality and precise dimensions.

Medical Industry

In the medical field, CNC metal machining is crucial for creating surgical instruments, implants, and prosthetic devices.

The precision and accuracy offered by this process ensure patient safety and the effectiveness of medical devices.

Defense Industry

The defense sector utilizes CNC metal machining for the production of firearms, ammunition, and other critical components for military applications.

The ability to machine complex geometries and tight tolerances is essential for meeting strict military standards.

Energy Industry

CNC metal machining plays a vital role in the energy sector, particularly in the production of parts for oil and gas exploration, power generation, and renewable energy systems.

This includes components for turbines, pumps, valves, and solar panel mounting systems.

General Manufacturing

CNC metal machining is also widely used in general manufacturing settings for the production of custom parts, tools, and fixtures.

It allows manufacturers to quickly adapt to changing product designs and market demands while maintaining high quality standards.

5 Things to Consider When Choosing a CNC Metal Machining Services

Material properties play a vital role in the selection of the right machining service. As a customer, you need to understand which CNC machining materials are appropriate for matching your needs.

Some common criteria include:

Corrosion resistance

Strength of material

Hardness

Ductility and Malleability

CNC machining techniques will depend on the type of material and so will the surface finish.

These parameters are also of paramount importance in choosing types of cutters and their metallurgy.

To make understanding easier, let us classify each of these parameters into quantifiable terms.

With an in-depth discussion of the material aspects covered above, now let us have a look at the various types of machining processes in CNC machining and how you can realize the types of operations required for your parts. The main types of machining processes in the CNC industry include:

Milling: The workpiece remains stationary while the tool rotates and performs machining

Drilling: Cutting of holes in the workpiece using a rotating tool

Turning: The workpiece rotates in a chuck while the tool remains stationary during machining

Grinding: Using an abrasive rotating wheel to remove material at a very gradual rate from the surface

Sawing: Cutting of blanks into pieces using a blade

Deburring: Removal of excess metal, sharp edges and ridges leftover from main machining operations

Polishing and Brushing: Improving the aesthetical look of the finished product by using a slightly abrasive machining process.

Typical machines used in the CNC industry are:

3, 4, and 5 axis CNC milling machine. 5 axis machining provides the most versatility.

CNC Turning Machine

Universal machining center

Grinding machine

While the aspects of material selection and machining processes are important, aesthetics of a part still play a major role in value-addition. What we can achieve from surface finish includes:

Rust protection

Exterior Decoration

Surface strengthening

As the name describes that surface finish is the process that follows the machining of metal parts. In some cases, the surface finish is purely for aesthetics while in other cases, it is important for the proper mating of parts in an assembly.

Some of the surface finish methods are as follows:

Nickel plating

Carburizing

Powder coating

Grinding

Tool selection in production has a significant impact when choosing CNC metal service. Every material has different characteristics that are linked to alloying elements and hardness. This influences the selection of cutting tool geometry, grades and cutting data.

Tool selection does not mean material characteristics only. While planning a successful metal-cutting operation, the following are important aspects to consider:

Workpiece material

Type of Cutting Oil

Shape of the workpiece

Machining conditions

Required level of surface quality

As a prospective customer, before you choose your service provider for CNC parts, costing is an aspect you must comprehensively understand.

Normally, customers go for instant quotes from various machining service providers. If you understand the dimension of costing yourself, you will have an upper hand to negotiate positively. Let us dive into it.

Broadly speaking, two types of costs are involved in machining:

Variable costs

Fixed costs

For this article, let us focus on variable costs i.e., that depend on the number of parts and operations. We can divide machining features into four classes:

1)Parts requiring rotary machining only

2)Parts involving prismatic features

3)Parts requiring slab features

4)Parts requiring pockets and holes

Working Principle of CNC Metal Machining Service

Designing the Part

CAD Software: The first step in the CNC machining process involves designing the part using CAD (Computer-Aided Design) software. This software allows the creation of a detailed 3D model of the part.

CAM Software: The CAD model is then imported into CAM (Computer-Aided Manufacturing) software, where the machining process is planned. This includes selecting the tools, determining the tool paths, and setting machining parameters such as feed rate and spindle speed.

Generating the G-Code

The CAM software generates the G-code, a programming language that CNC machines understand. G-code contains instructions that control the movement of the machine's tools, specifying their paths and operations.

Machine Setup

Loading the G-Code: The G-code is uploaded to the CNC machine's controller.

Fixture Setup: The workpiece is secured onto the machine's worktable using fixtures or clamps. Proper alignment and positioning are critical.

Tool Setup: The necessary cutting tools are loaded into the machine's spindle or tool holder. Tools must be correctly calibrated and positioned.

Machining Operation

Initialization: The CNC machine is powered on and initialized. This may include homing procedures where the machine moves to a reference point.

Execution of G-Code: The machine controller reads and executes the G-code instructions. This involves moving the machine's tools along the specified paths with high precision.

Cutting Process: The cutting tools interact with the workpiece to remove material according to the programmed paths. Different operations can be performed, such as drilling, milling, turning, and more.

Monitoring and Adjustment

Real-time Monitoring: Operators monitor the machining process, checking for any issues such as tool wear or machine errors. Many modern CNC machines have sensors and feedback systems for real-time monitoring.

Adjustments: If necessary, adjustments can be made to the feed rate, spindle speed, or tool paths to ensure optimal performance and accuracy.

Finishing and Inspection

Post-Processing: After machining, the workpiece might require additional finishing operations such as deburring, polishing, or heat treatment.

Quality Control: The finished part is inspected to ensure it meets the required specifications. This can involve measuring dimensions, surface finish, and other critical parameters using various inspection tools and techniques.

3 Common Support Softwares For CNC Metal Machining Service

CAD Software

CAD software allows the operator to produce 2D and 3D models of physical components used in product design and manufacturing. Aside from that, they function in providing design data to manufacturers. Examples include AutoCAD (2D and 3D), Inventor (3D), Blender, and SketchUp.

CAM Software

CAM software is suitable for creating G-codes from CAD models for those controls CNC machines. Consequently, a CNC machine has automation. Top examples include Fusion 360, SolidWorks, and AutoCAD.

CAE Software

CAE software allows product designers to mimic the performance of an intended product. Consequently, they can enhance product designs and helps engineers solve engineering-related issues. Examples include finite element analysis, multibody dynamics, and computational fluid dynamics.

4 CNC Machining Services for Project Success in the Renewable Energy Industry

Rapid CNC Machining

When choosing a method of fabrication for your renewable energy project, there are a lot of factors to consider, such as the requirements, materials, geometric features, and dimensional tolerances. But if you need to get your product to market quickly and want to reduce fabrication time with CNC machining, there's another consideration: Rapid CNC Machining.

Assembly

Whether you're launching new wind, solar, energy storage, or fuel cell technology, your renewable energy project may require assembly work. If that's the case, you may want to look for a vendor who offers turnkey management of complex assemblies, even for projects with multi-level BOMs and hundreds of parts. A one-stop, concept-to-completion approach can also help you save on production costs.

Finishing

While you may be satisfied with an "as machined" or "as milled" finish, there are many options when it comes to surface finishing for your CNC machined part. Finishing is the final step to improve a product's appearance, provide additional strength, and add other features to the design. Common finishing techniques for CNC parts include steps like anodizing, powder coating, and bead blasting.

Inspection

While intricate in-process control plans should be in place across a vendor's fleet of CNC machinery, your renewable energy project may have specific requirements for final inspection, such as validation testing to ensure the finished product matches the original design. For example, your fuel cell enclosure may need to withstand 120 mph winds or a snow load of 2.9 kPa.

CNC metal machining is a versatile process widely accepted in part and product manufacturing. However, sometimes it might not be the best method. Here are several alternative methods that you can consider:

3D Printing

3D printing is an additive manufacturing process that involves melting, depositing, and solidifying a material using instructions from a CAD or digital 3D model. Like CNC machining, it is automated. However, unlike CNC machining, it is more suitable for a simple design.

Injection Molding

Injection molding is a plastic manufacturing process that involves melting and injecting material into a prepared mold and letting it solidify. It operates using the same mechanism as other manufacturing processes, such as blow molding, overmolding, and insert molding. It is an important part of the mass fabrication of products.

Die Casting

Die casting is similar to injection molding. However, it is suitable for metals such as aluminum. It involves melting the metal and injecting it into a prepared mold. The injection method can be low or high, depending on the product's quality.

The decision of which CNC machining materials to use for your part ultimately depends on what you're looking to create, but here are some general tips to use as a brief CNC materials guide:

Consider Non-Metallic Materials: Don't assume metals are your best option. Non-metallic materials have become popular because they are lightweight yet durable - like foam you can mold into various shapes. Non-metals also retain small details during cutting. If your project seems like one that may benefit from the use of non-metals, plenty of options can benefit your final product.

Know the Difference Between Foams: Remember that rigid foam and carving foam serve different purposes. While both are lightweight and durable, rigid foam is best for parts with a focus on structural integrity and stability, while carving foam is often used as insulation and prototypes for molds.

Consider Phenolics: Phenolics are great options, especially when you need to adhere to specific regulations or specifications for military-related projects.

Learn About Different Plastics: You can choose from a wide variety of diverse plastics. Acetal is often used for bushing and bearing replacements. Polyvinylidene fluoride polymer, or PVDF, is used in insulation for electrical wiring. UHMW can be employed in medical biomaterial applications, such as knee, hip, and spine replacement devices. These are just a few examples of the endless possibilities offered by plastics.

Steps of CNC Machining Service

Analyze the Processing Drawings and Determine the Processing Method

Consistent with the processing drawings provided by the customer, the technicians analyze the shape, dimensional accuracy, surface roughness, workpiece material, blank type, and heat treatment status of the parts. They then select the machine tool and device, determine the clamping method, and decide on the processing approach.

Calculate the Coordinate Values of the Tool Path

Based on the geometric dimensions of the machined part and the programmed coordinate system, the movement direction of the tool path center is calculated, and all tool position information is obtained. Most CNC systems have linear and circular interpolation capabilities. For contour processing of planar components with relatively simple shapes (such as parts composed of straight lines and arcs), it is only necessary to calculate the starting point, endpoint, and center of the circle (or radius of the arc), and the coordinates of the intersection or tangent points of two geometric elements.

Write the CNC Machining Program

Based on the tool path of the part, the tool movement direction information, and the determined process parameters and auxiliary movements, the programmer can write the part's machining program step by step according to the functional instructions and program segment format specified by the CNC system used.

Our factory

We have precision casting production line and more than 60 kinds of machining equipments. Such as CNC lathes, Swiss CNC Lathe machine, 4 Axis machining centers, 5 Axis machining centers, wire cutting machines, milling machines, drilling machines and other equipments at state-of-the-art.

FAQ

Hot Tags: cnc metal machining service, China cnc metal machining service manufacturers, suppliers, factory