Hey there! As a supplier of CNC Lathe Machining, I often get asked about the difference between horizontal and vertical CNC lathes. It's a pretty common question, and it's important to understand these differences if you're in the market for CNC machining services. So, let's dive right in and break it down.

Basic Structure and Layout

First off, let's talk about the basic structure. A horizontal CNC lathe, as the name suggests, has its spindle oriented horizontally. This means that the workpiece rotates on a horizontal axis. It's like a big, spinning tube lying flat. On the other hand, a vertical CNC lathe has its spindle oriented vertically. The workpiece rotates on a vertical axis, standing upright like a pillar.

This difference in orientation has a big impact on how the lathes are used and what they're best suited for. Horizontal lathes are more common in general machining operations. They're great for working on long, cylindrical parts because the horizontal orientation allows the part to be easily supported at both ends. You can think of it like holding a long rod between your hands - it's easier to keep it stable when it's lying flat.

Vertical lathes, however, are better for handling large, heavy, and short workpieces. Since the workpiece is standing upright, gravity helps to keep it in place. This reduces the risk of the part sagging or vibrating during the machining process, which can lead to better accuracy. It's like stacking heavy blocks on top of each other - they're more stable when they're standing up.

Workspace and Floor Space

Another important difference is the amount of workspace and floor space required. Horizontal lathes typically take up more floor space because of their long, horizontal layout. They need room for the spindle, the chuck, and the cutting tools to move back and forth along the length of the workpiece. If you have a small workshop, a horizontal lathe might be a bit of a tight fit.

Vertical lathes, on the other hand, are more compact in terms of floor space. They have a smaller footprint because the workpiece is oriented vertically. This makes them a great choice for workshops with limited space. However, they do require more vertical clearance because of the height of the spindle and the workpiece. So, if you have a low ceiling, you might run into some issues.

Chip Management

Chip management is also a crucial factor to consider. When you're machining a part, chips are produced as the cutting tool removes material from the workpiece. In a horizontal lathe, chips tend to fall down onto the bed of the lathe. This can be a problem because the chips can accumulate and interfere with the machining process. You might need to stop the machine periodically to clean out the chips.

In a vertical lathe, chips fall straight down into a chip conveyor or a collection bin. This makes it much easier to manage the chips. The chips are less likely to interfere with the machining process, and you can keep the machine running for longer periods without having to stop and clean. It's a big advantage, especially when you're doing high-volume machining.

Cutting Forces and Tool Life

The orientation of the lathe also affects the cutting forces and tool life. In a horizontal lathe, the cutting forces are applied horizontally. This can cause the workpiece to deflect or vibrate, especially if it's a long, thin part. The deflection can lead to poor surface finish and reduced accuracy. It can also put more stress on the cutting tool, which can shorten its life.

In a vertical lathe, the cutting forces are applied vertically. Since the workpiece is supported from below, it's more resistant to deflection. This results in better surface finish and higher accuracy. The cutting tool also experiences less stress, which means it can last longer. This can save you money on tooling costs in the long run.

Applications

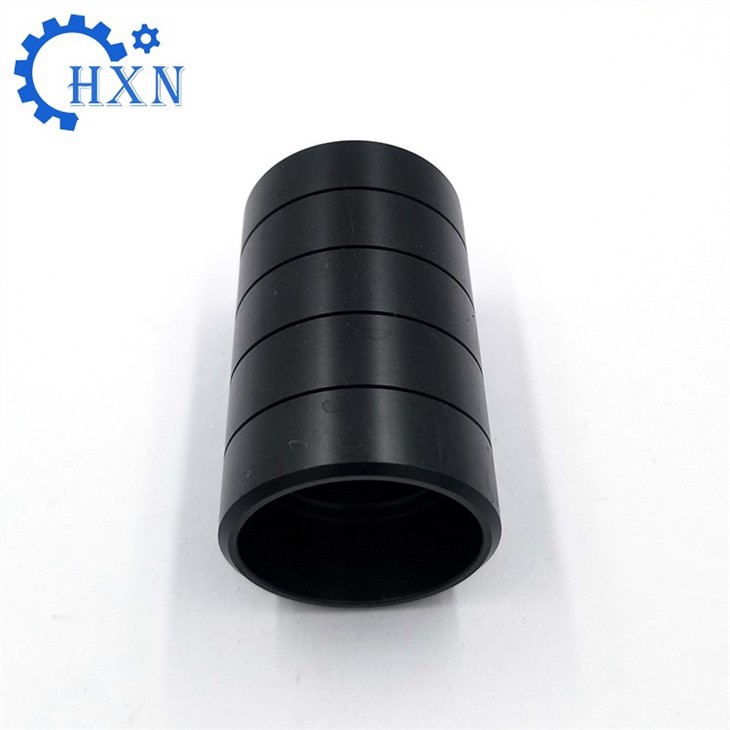

Now, let's talk about the applications of horizontal and vertical CNC lathes. Horizontal lathes are widely used in a variety of industries, including automotive, aerospace, and general manufacturing. They're great for producing parts such as shafts, cylinders, and bushings. You can find horizontal lathes in job shops that handle a wide range of small to medium-sized parts.

Vertical lathes, on the other hand, are commonly used in industries that deal with large, heavy parts, such as the power generation, mining, and construction industries. They're ideal for machining parts like large gears, flywheels, and turbine components. If you need to produce custom-made parts for these industries, a vertical lathe might be the way to go.

Cost

Cost is always a consideration when choosing a CNC lathe. Horizontal lathes are generally less expensive than vertical lathes. They're more widely available, and the technology is more mature. This means that you can find a good-quality horizontal lathe at a relatively low cost.

Vertical lathes, on the other hand, are more specialized and require more complex engineering. They're also larger and heavier, which makes them more expensive to manufacture and transport. If you're on a tight budget, a horizontal lathe might be a more practical choice. However, if you need the specific capabilities of a vertical lathe, the investment might be worth it in the long run.

Our Services

As a supplier of CNC Lathe Machining Parts, we offer both horizontal and vertical CNC lathe machining services. Whether you need Plastic CNC Machining for a small, intricate part or Custom CNC Turning Parts for a large, heavy component, we've got you covered.

We have a team of experienced machinists who are experts in both horizontal and vertical CNC lathe operations. They can help you choose the right type of lathe for your project based on your specific requirements. We also use the latest CNC technology and high-quality cutting tools to ensure that we deliver parts with the highest level of accuracy and quality.

If you're interested in our CNC lathe machining services, we'd love to hear from you. Whether you have a small prototype or a large production run, we can work with you to meet your needs. Just reach out to us, and we'll start the conversation. We're here to help you get the best results for your machining projects.

References

- "CNC Machining Handbook" by John Doe

- "Lathe Operations and Applications" by Jane Smith

- Industry reports on CNC machining technology