Hey there! As a precision casting supplier, I've been in the game for quite some time, and I've seen all sorts of quality standards come and go. Today, I'm gonna break down what the quality standards for precision casting are all about, and why they matter to you.

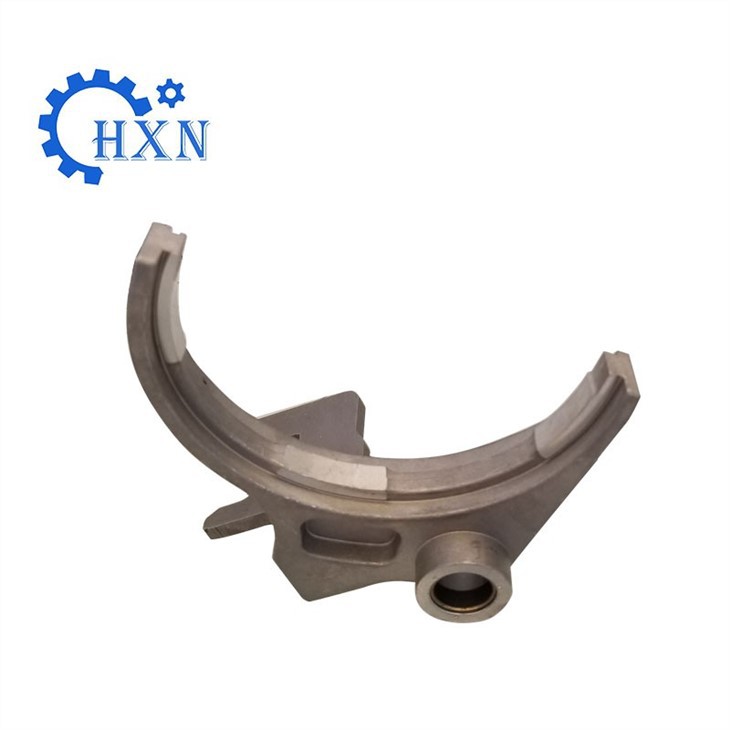

First off, let's talk about what precision casting actually is. It's a manufacturing process that creates complex parts by pouring molten metal into a mold. The end result is a part that has a high level of accuracy and a smooth surface finish. Precision casting is used in a wide range of industries, from aerospace to automotive, and even in jewelry making.

So, what are the quality standards for precision casting? Well, there are a few key factors that we consider when evaluating the quality of a cast part.

Dimensional Accuracy

One of the most important quality standards for precision casting is dimensional accuracy. This means that the part must be made to the exact specifications provided by the customer. Even the slightest deviation can cause problems down the line, such as poor fit or function.

To ensure dimensional accuracy, we use a variety of techniques. First, we create a detailed mold design that takes into account all the necessary dimensions and tolerances. Then, we use advanced manufacturing processes to cast the part as accurately as possible. Finally, we perform rigorous quality control checks using precision measuring tools to verify that the part meets the required specifications.

Surface Finish

Another important quality standard is surface finish. The surface of a precision casting should be smooth and free of defects. A rough or uneven surface can not only affect the part's appearance but also its performance. For example, a rough surface can cause increased friction, which can lead to premature wear and tear.

To achieve a high-quality surface finish, we use different casting techniques and post - processing methods. For instance, we might use a special wax pattern with a smooth surface to create the mold. After casting, we can perform operations like grinding, polishing, or sandblasting to improve the surface finish of the part.

Material Quality

The quality of the material used in precision casting is crucial. The material must be of the right grade and composition to ensure that the part has the desired mechanical properties, such as strength, hardness, and corrosion resistance.

We source our materials from reliable suppliers and conduct thorough material testing. We check for things like chemical composition, tensile strength, and density to make sure that the material meets the required standards. For example, if we're casting a part for the aerospace industry, we need to ensure that the material can withstand high temperatures and extreme pressures.

Porosity and Internal Defects

Porosity and internal defects can significantly affect the strength and integrity of a precision casting. Porosity refers to the presence of small holes or voids in the material, which can weaken the part. Internal defects, such as cracks or inclusions, can also lead to part failure.

To minimize porosity and internal defects, we carefully control the casting process. We pay attention to factors like the pouring temperature, pressure, and speed to ensure that the molten metal fills the mold evenly and smoothly. We also use advanced inspection techniques like X - ray or ultrasonic testing to detect any internal defects in the cast parts.

Certification and Compliance

In many industries, precision cast parts need to meet certain industry standards and certifications. For example, parts used in the medical industry might need to comply with strict FDA regulations, while parts for the automotive industry might need to meet ISO standards.

As a responsible precision casting supplier, we make sure that our parts are compliant with all the relevant standards. We have a quality management system in place to ensure that every step of the manufacturing process is in line with these standards. This not only gives our customers peace of mind but also helps us to stay competitive in the market.

Now, let me tell you a bit about the different types of precision casting we offer. We specialize in Aluminium Casting Manufacturers. Aluminium is a popular choice for precision casting because it's lightweight, has good corrosion resistance, and is easy to cast. Our aluminium casting parts are widely used in industries like electronics, automotive, and aerospace.

We also offer Aluminum & Zinc Die Casting. Die - casting is a fast and efficient way to produce high - volume precision parts. Aluminum and zinc are commonly used in die - casting due to their excellent casting properties and mechanical characteristics.

Another area we're good at is Clay Sand Casting Parts. Clay sand casting is a traditional and cost - effective method, which is suitable for producing large and medium - sized parts. It can be used to make parts with complex shapes and good mechanical properties.

If you're in the market for precision casting parts, we'd love to hear from you. Whether you need a single prototype or a large - scale production run, we have the expertise and capabilities to meet your needs. We'll work closely with you from the design stage to the final delivery to ensure that you get high - quality precision casting parts that meet your exact requirements. So, don't hesitate to reach out and start a procurement discussion with us.

References

- ASM Handbook: Volume 15 - Casting

- Metals Handbook Desk Edition

- Precision Casting Technology Textbooks