Hey there! As a supplier of Stainless Steel Bushing, I often get asked about the dimensional tolerances of stainless steel bushings. So, I thought I'd write a blog post to share some insights on this topic.

What are Dimensional Tolerances?

Before we dive into the specifics of stainless steel bushings, let's first understand what dimensional tolerances are. In simple terms, dimensional tolerances are the allowable variations in the size and shape of a part. When a part is manufactured, it's almost impossible to make it exactly to the specified dimensions. There will always be some small variations due to factors like machining processes, tool wear, and material properties.

Dimensional tolerances are important because they ensure that parts fit together properly and function as intended. If a part is too big or too small, it may not fit into the assembly, or it may not perform its intended function. So, manufacturers use dimensional tolerances to specify the acceptable range of variation for each dimension of a part.

Dimensional Tolerances of Stainless Steel Bushings

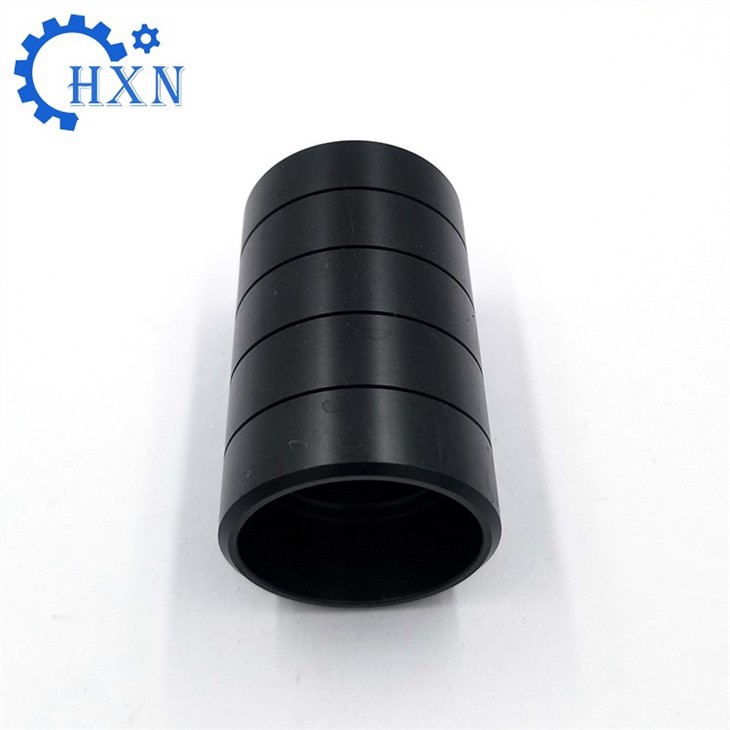

Now, let's talk about the dimensional tolerances of stainless steel bushings. Stainless steel bushings are used in a wide range of applications, from automotive and aerospace to industrial machinery and consumer products. The dimensional tolerances of stainless steel bushings can vary depending on the specific application and the requirements of the customer.

Outer Diameter (OD) Tolerances

The outer diameter of a stainless steel bushing is one of the most critical dimensions. It needs to fit precisely into the housing or bore where it will be installed. The OD tolerances of stainless steel bushings typically range from ±0.001 inches to ±0.005 inches, depending on the size and application of the bushing.

For example, in a high-precision application like aerospace or medical equipment, the OD tolerance may be as tight as ±0.001 inches. This ensures a precise fit and minimizes any play or movement between the bushing and the housing. On the other hand, in a less critical application like a consumer product or a general industrial machine, the OD tolerance may be looser, around ±0.005 inches.

Inner Diameter (ID) Tolerances

The inner diameter of a stainless steel bushing is also important, as it needs to fit over the shaft or pin that it will be used with. The ID tolerances of stainless steel bushings are usually similar to the OD tolerances, ranging from ±0.001 inches to ±0.005 inches.

In some cases, the ID tolerance may be even more critical than the OD tolerance. For example, if the bushing is used in a high-speed application, a tight ID tolerance is necessary to ensure smooth rotation and minimize friction. In such cases, the ID tolerance may be specified as ±0.0005 inches or even tighter.

Length Tolerances

The length of a stainless steel bushing is another dimension that needs to be controlled. The length tolerances of stainless steel bushings typically range from ±0.002 inches to ±0.010 inches, depending on the length of the bushing and the application.

For shorter bushings, the length tolerance may be tighter, around ±0.002 inches. This is because a small variation in length can have a significant impact on the fit and performance of the bushing. For longer bushings, the length tolerance may be looser, around ±0.010 inches.

Wall Thickness Tolerances

The wall thickness of a stainless steel bushing is also an important dimension. The wall thickness tolerances of stainless steel bushings typically range from ±0.001 inches to ±0.005 inches, depending on the size and application of the bushing.

A consistent wall thickness is important for the strength and durability of the bushing. If the wall thickness varies too much, it can affect the performance of the bushing and may even lead to premature failure.

Factors Affecting Dimensional Tolerances

There are several factors that can affect the dimensional tolerances of stainless steel bushings. Some of the most important factors include:

Machining Processes

The machining processes used to manufacture stainless steel bushings can have a significant impact on the dimensional tolerances. For example, turning, milling, and grinding are common machining processes used to make stainless steel bushings. Each of these processes has its own limitations and capabilities when it comes to achieving tight dimensional tolerances.

Turning is a relatively simple and cost-effective machining process that can produce bushings with good dimensional accuracy. However, it may not be able to achieve the same level of precision as grinding. Grinding is a more precise machining process that can produce bushings with very tight dimensional tolerances. However, it is also more expensive and time-consuming.

Tool Wear

Tool wear is another factor that can affect the dimensional tolerances of stainless steel bushings. As the cutting tools used in machining wear down, they can produce parts with dimensions that are slightly different from the specified dimensions. To minimize the impact of tool wear, manufacturers need to monitor the condition of their cutting tools and replace them when necessary.

Material Properties

The material properties of stainless steel can also affect the dimensional tolerances of bushings. Stainless steel is a relatively hard and tough material, which can make it more difficult to machine compared to other materials. The hardness and toughness of stainless steel can cause the cutting tools to wear down more quickly, which can affect the dimensional accuracy of the parts.

In addition, the thermal properties of stainless steel can also affect the dimensional tolerances. Stainless steel has a relatively high coefficient of thermal expansion, which means that it can expand and contract significantly when exposed to changes in temperature. This can cause the dimensions of the bushing to change, which can affect its fit and performance.

Inspection and Quality Control

Inspection and quality control are essential for ensuring that stainless steel bushings meet the specified dimensional tolerances. Manufacturers need to use a variety of inspection tools and techniques to measure the dimensions of the bushings and ensure that they are within the acceptable range.

Some of the common inspection tools used for measuring the dimensions of stainless steel bushings include calipers, micrometers, and coordinate measuring machines (CMMs). These tools can provide accurate and precise measurements of the outer diameter, inner diameter, length, and wall thickness of the bushings.

In addition to using inspection tools, manufacturers also need to implement a comprehensive quality control system to ensure that the bushings are manufactured to the highest standards. This includes processes for monitoring the machining processes, inspecting the raw materials, and testing the finished products.

Importance of Dimensional Tolerances in Stainless Steel Bushings

The dimensional tolerances of stainless steel bushings are crucial for ensuring their proper fit, performance, and durability. Here are some of the key reasons why dimensional tolerances are important:

Proper Fit

Stainless steel bushings need to fit precisely into the housing or bore where they will be installed. If the OD or ID of the bushing is too big or too small, it may not fit properly, which can lead to problems like excessive play, vibration, and noise. By controlling the dimensional tolerances, manufacturers can ensure that the bushings fit snugly and securely into the assembly.

Smooth Operation

A tight dimensional tolerance is necessary for ensuring smooth operation of the bushing. If the ID of the bushing is too loose, it can cause the shaft or pin to wobble, which can lead to increased friction and wear. On the other hand, if the ID is too tight, it can make it difficult for the shaft or pin to rotate, which can also cause excessive friction and wear. By maintaining the proper dimensional tolerances, manufacturers can ensure that the bushing operates smoothly and efficiently.

Durability

The dimensional tolerances of stainless steel bushings also affect their durability. If the wall thickness of the bushing is not consistent, it can cause stress concentrations, which can lead to premature failure. By controlling the dimensional tolerances, manufacturers can ensure that the bushing has a uniform wall thickness and is able to withstand the loads and stresses that it will be subjected to in service.

Conclusion

In conclusion, the dimensional tolerances of stainless steel bushings are an important aspect of their design and manufacturing. By understanding the factors that affect dimensional tolerances and implementing appropriate quality control measures, manufacturers can ensure that their stainless steel bushings meet the specified requirements and perform reliably in a wide range of applications.

If you're in the market for high-quality Stainless Steel Bushing, look no further. As a leading supplier, we have the expertise and experience to provide you with bushings that meet your exact specifications and requirements. Whether you need a standard bushing or a custom-designed solution, we can help.

Feel free to reach out to us to discuss your needs and get a quote. We're always happy to help and look forward to working with you.

References

- ASME Y14.5 - Dimensioning and Tolerancing Standard

- ISO 286 - Geometrical Product Specifications (GPS) - Linear Sizes - Tolerance Grades and Geometric Tolerances for Cylindrical Parts