In the realm of modern manufacturing, both CNC turning service and laser cutting are indispensable techniques, each with its own unique characteristics, advantages, and application scenarios. As a provider of CNC turning service, I am well - versed in the intricacies of this process and can offer a detailed comparison with laser cutting.

1. Basic Principles

CNC Turning Service

CNC turning is a subtractive manufacturing process. It involves rotating a workpiece on a lathe while a cutting tool is fed into it to remove material. The cutting tool moves along different axes (usually X and Z in a basic setup) under the control of a computer numerical control (CNC) system. This system precisely dictates the movement of the tool, allowing for the creation of highly accurate cylindrical or conical shapes. For example, when manufacturing a simple shaft, the workpiece is clamped in the chuck of the lathe and rotates at a specific speed. The cutting tool then moves in a coordinated manner to shape the shaft to the desired diameter and length.

Laser Cutting

Laser cutting, on the other hand, is a thermal separation process. It uses a high - power laser beam focused on the material surface. The intense heat of the laser beam melts, vaporizes, or burns through the material, creating a cut. The laser beam is guided by a CNC system as well, which controls the movement of the laser head along the programmed path. For instance, when cutting a sheet of metal, the laser head moves across the surface, and the laser beam cuts through the metal with high precision.

2. Material Compatibility

CNC Turning Service

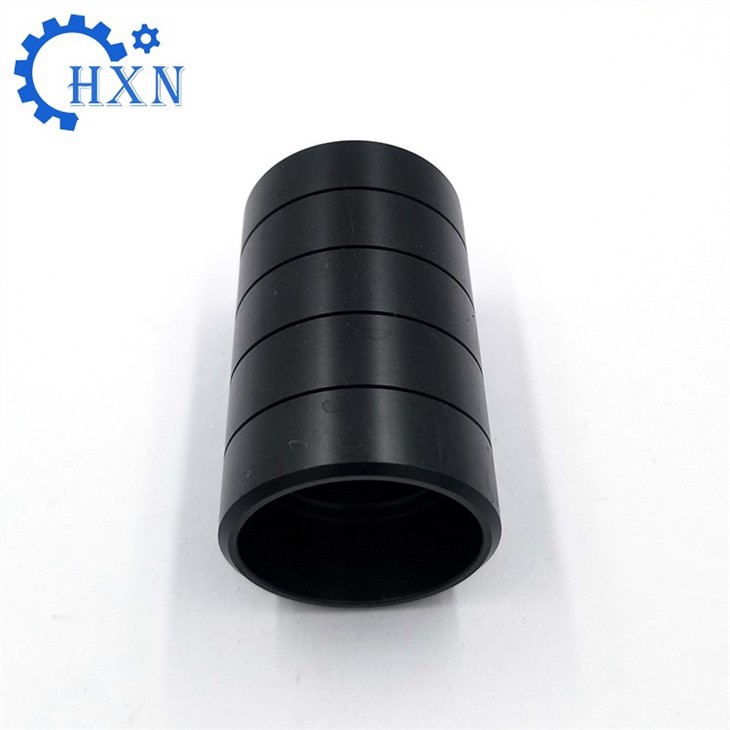

CNC turning is highly versatile in terms of material compatibility. It can work with a wide range of materials, including metals such as aluminum, steel, brass, and titanium. These metals can be easily shaped into various components with different geometries. Additionally, plastics are also commonly used in CNC turning. Plastic Cnc Service offers great flexibility in creating plastic parts with complex shapes. For example, plastic gears or bushings can be precisely machined using CNC turning. However, extremely hard or brittle materials may pose challenges as they can cause excessive tool wear or breakage.

Laser Cutting

Laser cutting is also compatible with multiple materials. Metals, especially thin sheets of steel, aluminum, and stainless steel, are frequently cut using lasers. Non - metallic materials like wood, acrylic, and some types of plastics can also be laser - cut. But when it comes to certain plastics, laser cutting may produce fumes or cause discoloration. For example, some types of PVC can release toxic fumes when laser - cut, which requires proper ventilation systems.

3. Precision and Tolerance

CNC Turning Service

One of the key strengths of CNC turning is its ability to achieve high precision and tight tolerances. Modern CNC lathes can hold tolerances as tight as ±0.005 mm or even better in some cases. This makes it ideal for manufacturing parts that require high accuracy, such as Precision CNC Turning Parts. For example, in the aerospace industry, engine components need to be machined with extremely high precision to ensure proper functioning and safety.

Laser Cutting

Laser cutting can also provide high precision, especially for thin materials. It can achieve tolerances in the range of ±0.1 mm for thin sheets. However, as the material thickness increases, maintaining high precision becomes more challenging. Thick materials may experience some taper in the cut, which can affect the overall accuracy of the part.

4. Surface Finish

CNC Turning Service

The surface finish obtained from CNC turning can be quite good. By using appropriate cutting tools and machining parameters, a smooth surface can be achieved. The surface finish is typically measured in terms of Ra (average roughness). With proper optimization, Ra values as low as 0.8 - 1.6 μm can be obtained. This smooth surface finish is beneficial for parts that require low friction or good aesthetics. For example, shafts in mechanical systems need a smooth surface to reduce wear and improve efficiency.

Laser Cutting

The surface finish of laser - cut parts depends on several factors, including the material, laser power, and cutting speed. In general, laser - cut edges may have a slightly rough or striated appearance. For some applications, this may not be a problem, but for parts that require a very smooth surface, additional finishing operations may be necessary.

5. Production Speed

CNC Turning Service

The production speed of CNC turning depends on the complexity of the part and the material being machined. For simple cylindrical parts, the machining process can be relatively fast. However, for parts with complex geometries, such as those with multiple diameters, grooves, and threads, the production time can increase significantly. The cutting tool needs to make multiple passes to achieve the desired shape, which can slow down the overall process.

Laser Cutting

Laser cutting is generally fast for cutting flat sheets or simple 2D shapes. It can quickly cut through large areas of material, especially thin sheets. However, for 3D or complex shapes, the laser cutting process may need to be combined with other operations, which can increase the overall production time.

6. Cost

CNC Turning Service

The cost of CNC turning is influenced by several factors. The cost of raw materials, tooling, and machine time all contribute to the overall cost. For high - volume production, the cost per part can be relatively low as the setup cost can be spread over a large number of parts. However, for low - volume production, the setup cost, which includes programming the CNC machine and preparing the tooling, can be a significant portion of the total cost.

Laser Cutting

The cost of laser cutting also depends on material, thickness, and complexity. Laser cutting machines are generally more expensive to purchase and maintain compared to CNC lathes. However, for thin - sheet cutting and simple 2D shapes, the cost per part can be competitive, especially for small - to - medium - volume production.

7. Design Flexibility

CNC Turning Service

CNC turning offers great design flexibility for parts with rotational symmetry. It can create a wide range of cylindrical, conical, and spherical shapes. Features such as threads, grooves, and tapers can be easily incorporated into the design. However, for non - rotational or highly complex 3D shapes, CNC turning may have limitations. In such cases, additional machining operations or other manufacturing processes may be required.

Laser Cutting

Laser cutting is highly flexible for 2D designs. It can cut almost any 2D shape, no matter how complex, as long as the laser can reach all the areas. For 3D shapes, laser cutting can be combined with other processes like bending or folding to create more complex structures.

8. Application Areas

CNC Turning Service

CNC turning is widely used in various industries. In the automotive industry, it is used to manufacture engine components, shafts, and gears. In the medical field, precision parts such as surgical instruments and implants are often produced using CNC turning. The aerospace industry also relies on CNC turning for manufacturing high - precision components. Plastic CNC Machining is also crucial in industries where lightweight and corrosion - resistant plastic parts are required.

Laser Cutting

Laser cutting is commonly used in industries such as sheet metal fabrication, signage, and electronics. In sheet metal fabrication, it is used to cut parts for enclosures, brackets, and frames. In the signage industry, it can create precise and detailed lettering and designs on various materials. In electronics, it is used to cut circuit boards and other thin components.

In conclusion, both CNC turning service and laser cutting have their own unique advantages and limitations. The choice between the two depends on various factors such as the material, part design, precision requirements, production volume, and cost. As a provider of CNC turning service, I can offer high - quality solutions for a wide range of applications. If you are in need of precision - machined parts, whether it's for a small - scale project or large - volume production, I encourage you to contact me for a detailed discussion and to explore how CNC turning can meet your specific needs. Let's work together to bring your ideas to life and achieve the best results for your manufacturing projects.

References

- "Modern Manufacturing Processes" by John A. Schey

- "CNC Machining Handbook" by Peter Smid

- "Laser Cutting Technology: Principles and Applications" by James E. Harry