Hey there! As a supplier of OEM Cnc Milling Parts, I've seen firsthand how crucial it is to evaluate the quality of these parts. Whether you're a manufacturer looking for reliable components or a buyer in search of the best products, understanding how to assess quality is key. In this blog post, I'll share some tips and insights on how to evaluate the quality of OEM Cnc Milling Parts.

Material Quality

The first thing to consider when evaluating OEM Cnc Milling Parts is the material quality. The material used in the manufacturing process can significantly impact the performance and durability of the parts. As a supplier, I always ensure that we use high-quality materials for our OEM CNC Milling Parts.

- Material Grade: Check the grade of the material. For example, in the case of metals, different grades have different properties such as strength, corrosion resistance, and hardness. A higher-grade material generally means better performance and longer lifespan.

- Material Certification: Reputable suppliers should be able to provide material certifications. These documents confirm the quality and composition of the material used. It's a good idea to ask for these certifications before making a purchase.

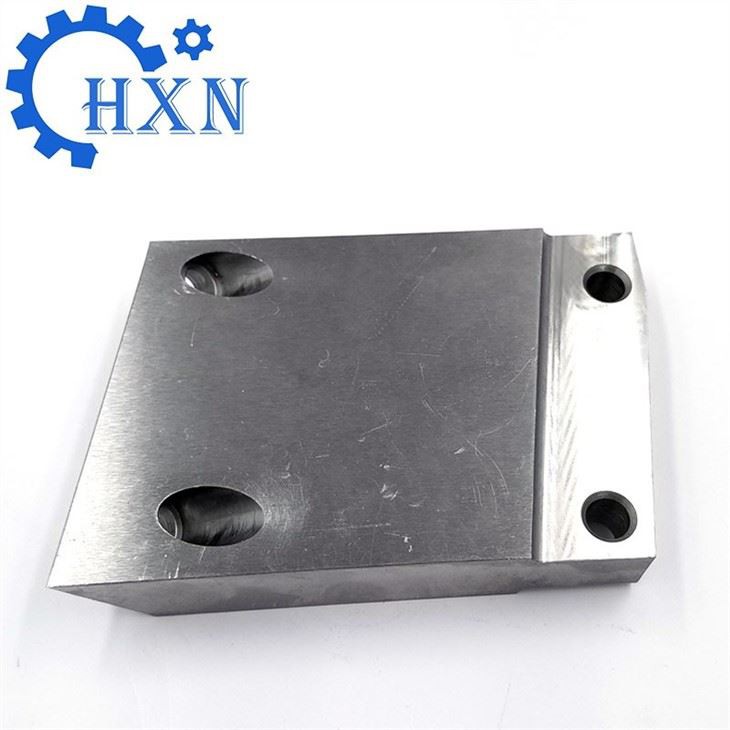

- Visual Inspection: Sometimes, a simple visual inspection can give you an idea of the material quality. Look for any signs of defects, such as cracks, porosity, or uneven surfaces. If the material looks rough or has visible flaws, it might not be of good quality.

Dimensional Accuracy

Dimensional accuracy is another critical factor in evaluating OEM Cnc Milling Parts. The parts need to meet the specified dimensions precisely to fit properly in the final product.

- Tolerance Levels: Every part has a tolerance level, which is the acceptable range of variation from the specified dimensions. A lower tolerance means higher precision. When evaluating parts, make sure the tolerance levels meet your requirements.

- Measurement Tools: To check the dimensional accuracy, you can use measurement tools such as calipers, micrometers, or coordinate measuring machines (CMMs). These tools can provide accurate measurements and help you determine if the parts are within the specified tolerances.

- CAD/CAM Comparison: If you have the CAD (Computer-Aided Design) model of the part, you can compare it with the actual part. This can be done using software that can analyze the differences between the digital model and the physical part.

Surface Finish

The surface finish of OEM Cnc Milling Parts can affect their functionality, appearance, and corrosion resistance.

- Surface Roughness: Surface roughness is a measure of the irregularities on the surface of the part. A smoother surface finish is often preferred, especially for parts that need to slide or fit tightly with other components. You can use a surface roughness tester to measure the surface roughness.

- Surface Defects: Look for any surface defects such as scratches, tool marks, or burrs. These defects can not only affect the appearance but also the performance of the part. For example, scratches can create stress concentration points, which may lead to premature failure.

- Coatings and Treatments: Some parts may have coatings or treatments applied to improve their surface properties. For example, a coating can provide corrosion resistance or reduce friction. Make sure the coatings are applied evenly and adhere well to the surface.

Machining Process

The machining process used to manufacture the OEM Cnc Milling Parts can also impact their quality.

- CNC Programming: The CNC (Computer Numerical Control) program controls the movement of the milling machine. A well-written program ensures accurate and efficient machining. Ask the supplier about their CNC programming practices and how they ensure the quality of the programs.

- Machine Quality: The quality of the milling machine used can also affect the part quality. High-quality machines are more precise and reliable. Reputable suppliers usually invest in modern and well-maintained machines.

- Tooling: The cutting tools used in the machining process can wear out over time, which can affect the surface finish and dimensional accuracy of the parts. Make sure the supplier has a proper tooling management system in place to ensure that the tools are replaced when necessary.

Testing and Inspection

A reliable supplier should have a comprehensive testing and inspection process in place to ensure the quality of their OEM Cnc Milling Parts.

- In-Process Inspection: This involves inspecting the parts during the machining process. It helps to identify and correct any issues early on, reducing the chances of producing defective parts.

- Final Inspection: After the parts are machined, they should undergo a final inspection. This can include dimensional checks, surface finish measurements, and functional tests.

- Quality Control Certificates: Ask the supplier for quality control certificates. These documents provide evidence that the parts have passed the necessary inspections and meet the specified quality standards.

Supplier Reputation

The reputation of the supplier is also an important factor to consider when evaluating OEM Cnc Milling Parts.

- Customer Reviews: Look for customer reviews and testimonials online. This can give you an idea of the supplier's reliability, quality of products, and customer service.

- Industry Experience: A supplier with more industry experience is likely to have better knowledge and expertise in manufacturing high-quality parts.

- Certifications and Awards: Check if the supplier has any relevant certifications or awards. These can be a sign of their commitment to quality and continuous improvement.

Cost vs. Quality

When evaluating OEM Cnc Milling Parts, it's important to consider the balance between cost and quality. While it's tempting to go for the cheapest option, it may not always be the best choice in the long run.

- Value for Money: Instead of just looking at the price, consider the value for money. A slightly more expensive part that offers better quality and performance may save you money in the long term by reducing the need for repairs or replacements.

- Total Cost of Ownership: Take into account the total cost of ownership, which includes not only the purchase price but also the cost of maintenance, repairs, and downtime. A high-quality part may have a lower total cost of ownership.

Conclusion

Evaluating the quality of OEM Cnc Milling Parts is a multi-faceted process that involves considering various factors such as material quality, dimensional accuracy, surface finish, machining process, testing and inspection, supplier reputation, and cost. By following these tips, you can make an informed decision and choose the best parts for your needs.

If you're interested in our OEM ODM CNC Milling Service or CNC Metal Machining Service, feel free to reach out to us for a quote or to discuss your requirements. We're committed to providing high-quality parts and excellent customer service.

References

- "CNC Machining Handbook" by John Doe

- "Quality Control in Manufacturing" by Jane Smith